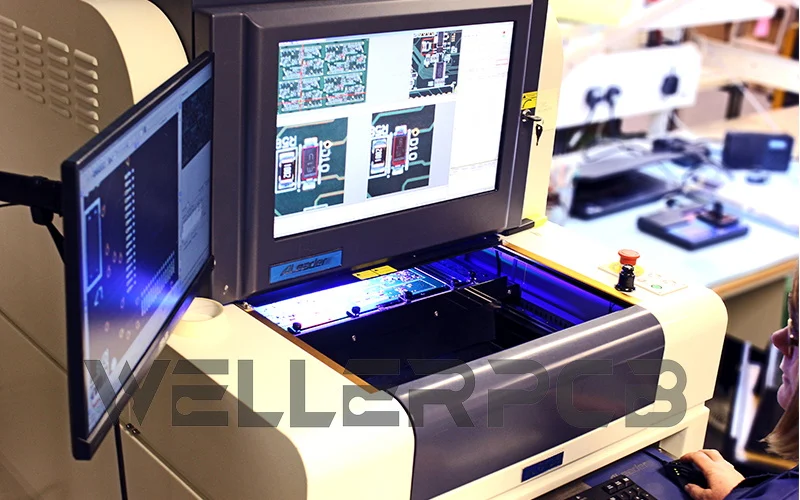

Automatic Optical Inspection (AOI)

Automated Optical Inspection, also called Automatic Optical Inspection, abbreviated as AOI, is well responsible for quality control in terms of both Printed Circuit Board (PCB) fabrication and PCB Assembly.

AOI system will identify the following types of unacceptable deviations:

Some of these mistakes is what is termed “false errors” where AOI system iteratively learns new approved week codes, texts, etc.., So the system gets better and better the more we use it.

The data and information we get from the AOI system, is used for multiple purposes in our production process

This information will also be available to our customers, so they also have the opportunity to optimize their design according to our “Design for manufacturing” philosophy.

All PCBAs are registered in our system. Defective boards will be sent to a separate repair station, where the operator will see the specific error on the inspected board on the screen of the repair station. Correction of the defective board will be very efficient and can be performed in parallel with ongoing production. Once the defective board has been fixed it will once again be checked in AOI system, before it can proceed to the next process in the production.