About WELLER

WELLER is an Electronic Manufacturing Services provider that specializes in high density Printed Circuit Board Design/Layout, high quality PCB Manufacturing&Assembly and Cable & Wire-Harness. We provide global solutions for seamless migration of customer’s design with our full turnkey services. As a technology-based company, we strive to meet our customer’s electrical, electronic manufacturing and injection molded plastics needs.

We are dedicated to deliver advanced technical expertise, professional engineering support, innovative manufacturing solutions, dedication with a high level of quality and service to all of our customer-partners. Quick-turn around, flexibility, reliability and results make us your ideal partner for Electronic Manufacturing Services.

Trusted for unsurpassed quality, service and on time delivery, WELLER focus on electronic assembly as we as manufacturing Rigid, Flex & Rigid-flex PCB fabrication for today’s most technical designs.

Our excellent in-house engineering support are top notch. Be it a simple or a complex design, our knowledgeable team helps & supports our customers with the most technical designs.

As an ISO 9001:2015 certified electronic manufacturing manufacturer, we perform quality inspection with 100% statistical process control, customer satisfaction is guaranteed whether for prototype, pre-production, or production runs.

Changes are inevitable with the growth and development in electronic industry; our production has been upgrading and keeping efficient. However, we remain a small company at heart, with the versatility to accommodate a wide variety of client needs, and the disposition to ensure these needs are sufficiently met. Over the times, we’ve worked with multiple-industries and WELLER has proven, again and again, that we have ability to supply for all Industries.

WELLER’s goal has been to provide comprehensive electronics manufacturing services right here in our own local facility and machining services through our partners. Whatever changes may come for our industry and for our company, we will be always dedicated to creating custom electronics manufacturing solutions for clients in aviation, rail, transit, OEM, and defense.

Working With WELLER

Milestones:

Year

Description

2023

2022

2020

2016

2010

2005

2003

Working with WELLER: 5 Phase Co-Development Process

Information Collecting

The client and WELLER discuss and collect the primary requirements and goals for the project. Typically an NDA is executed before starting, followed by communications (by e-mail/web/phone/instant message tooling) to gather up the various details, which can include the following:

Whether you have a new idea to create from the ground up, or want to optimize upon an existing product, WELLER’s talented team has developed processes to efficiently progress through each stage of a project to quickly deliver the most cost-effective modules that fully meet your technical requirements.

Feasibility Evaluation

Generally, WELLER often proposes an initial ‘Feasibility Evaluation’ during which engineering work can be completed to provide an initial assessment of the project. WELLER deliverables from the feasibility evaluation can include:

This phase can be iterative and concludes when the clients and WELLER agree on a technically and commercially acceptable approach to developing the desired end product.

WELLER will generate a proposal for development and production supply. At this phase, some development costs and production pricing may still be preliminary and subject to change. The project proceeds upon receipt of purchase order and agreement from customer.

Detail Design, Prototypes, Manufacturing Process Development

It is very important that final design requirements are provided by customer before beginning the detailed design phase. The following are activities that are commonly involved:

Prototype Build

Note: In some projects, particularly those involving multiple bare die, WELLER and customer may agree that a dual-stage prototype approach may be taken. For example, a quick prototype build using all packaged parts may be quickly designed and built so that the hardware design can be validated and software work can begin before the final production design using bare die is available.

Manufacturing Process Development

Depending on the complexity of the manufacturing process, ISI may engage in multiple small pre-production builds to fine-tune the manufacturing process and increase production yield.

Production Test Development and Qualification Testing

Specifically, the specific details of production test procedures are very specific to each product.

Production test development can begin along with the Detailed Design Stage, so that any test fixtures and software can be developed before the prototypes are available. The production test is then finalized and validated once functional prototypes are available.

WELLER has a variety of electronic test equipments and capabilities. The test development can be wholly developed by WELLER or it can be jointly developed by WELLER and clients, which is typical for functional tests that replicate actual customer usage. WELLER does have approved partners that can provide specialty testing as an outside service as required.

Qualification Testing

As required for the project, WELLER will develop and execute a qualification plan for the final product. This is typically a suite of tests to CE or FCC requirements.

The qualification test is specifically developed depending on the part design and the requirement of market filed that it sell to, how it will be used, and what environment it will be exposed to. Typical elements of product qualification testing include:

Production

WELLER can quickly ramp to production volumes. We utilize the same process and equipment for production parts that was developed during the prototype and pre-production builds.

Our ISO9001:2015 certified manufacturing facility manufactures to IPC Class 3 standards, and we have IPC certified operators in house.

All the materials used by WELLER must be certificated by UL. And all materials we used must be traceable.

WELLER’s manufacturing facility has been audited and approved by many of the Europe and America smart electronic companies.

Industries We Serve

Aersopace and Defense

Complex specifications, rigorous production processes and the highest levels of compliance are demanded by the aerospace and defense industries.

WELLER can manufacture your product to meet those special requirements to operate as intended.

Medical & Life Sciences

Our ISO13485 compliant capabilities, experienced engineering team, together with an advanced SMT equipments and high grade of production facility enable us to supply a wide range of compliant, high quality PCB fabrication and PCB assembly products to the medical device industry.

Transportation

Our strict adherence to quality is of significant benefit to our customers and this is evidenced by our IATF 16949 certifications. We fully understand the quality standards required by our automotive customers and Advanced Product Quality Planning (APQP), Product Part Approvals (PPAP)…

Communications

New 5G networking technology and satellite communication systems require hardware capable of optimizing bandwidth usage and ensuring secure and reliable communications. WELLER experienced engineering team can help customers develop and deliver communications hardware which will meet the ever increasing needs of the industry.

Energy-Clean Technology

Energy market – whether that be in Clean Energy, Smart Energy or the traditional Oil & Gas sector, WELLER’s unique design and manufacturing capabilities can optimize Oil & Gas related electronic devices to deliver greater value into the fast-changing Energy segment.

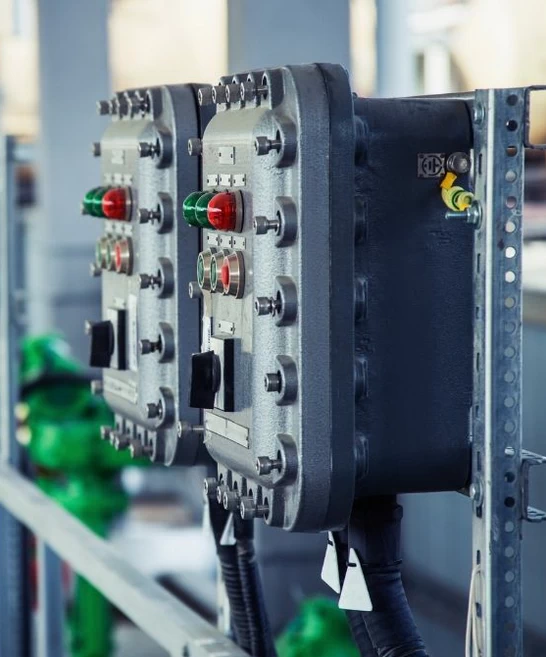

Industrial & Commercial

We have significant experience assisting our customers with the design of industrial and commercial electronic products. Our Embedded Systems group has a full range of off-the-shelf solutions as well as the experience and skills set required to create bespoke solutions.

Niche Consumer

During our 10+ years as a trusted EMS provider, we have worked consistently with a unique segment of the consumer device industries that is termed ‘Niche Consumer’ . WELLER only focus on a significantly higher quality and reliability level but a competitive cost.

Security & Life Safety

Whether you are designing a completely new system or redeveloping an obsolete product, our experienced electronics engineers and technicians will implement full turnkey designs per your specifications, or work collaboratively with your team to identify and develop selected subsets of your product.