What Are Ultrasonics?

From the singing of birds to the wind Whispering is more than just what we can hear with our ears. It come out from the mechanical vibration of bodies. This doesn’t only happen in the air, but in every elastic medium, i.e. gases, liquids, and solids.

Ultrasonics are an example of the fact that humans cannot hear every type of sound. High-frequency sound waves are widely used in industry and medicine, and these cannot be heard.

Sound waves are Sound waves are defined and categorized by their frequency (number of waves per second). For example, ultrasonics frequency typicality range from 20 kHz to 1 GHz. Ultrasonic welding are widely applied to industrial field, using frequencies from 20 kHz to 70 kHz. The lowest range of this can still just be heard by human ears. This is because audible sound (for humans at least) has a range of frequency only from 16 Hz to 20 kHz. At most, oscillations going above this are perceived as vibrations.

How Does Ultrasonic Welding Work?

Ultrasonic plastic welding is the reforming or joining of thermoplastics material through the use of heat energy generated from high-frequency mechanical motion. It is done by converting high-frequency electrical energy into high-frequency mechanical motion. When the ultrasonic vibrations hit a material (e.g. a plastic), the molecular chains begin to oscillate. The molecules begin to move and rub against each other. The energy (referred to as friction heat) generated in this process. In the case of thermoplastic materials, this process drive them to start to melt. Ultrasonic welding takes advantage of this principle. After a short hold time under additional pressure, the plastic materials can be bonded together at a molecular level in the joining area.

What Is Ultrasonic Welding Suitable For?

Ultrasonic welding happens in split seconds without the need for any extra aids such as adhesives or screws. Ultrasonics are widely used to create packaging, car parts, toys, industrial enclosure and much more, for example, by:

The Ultrasonic Welding System

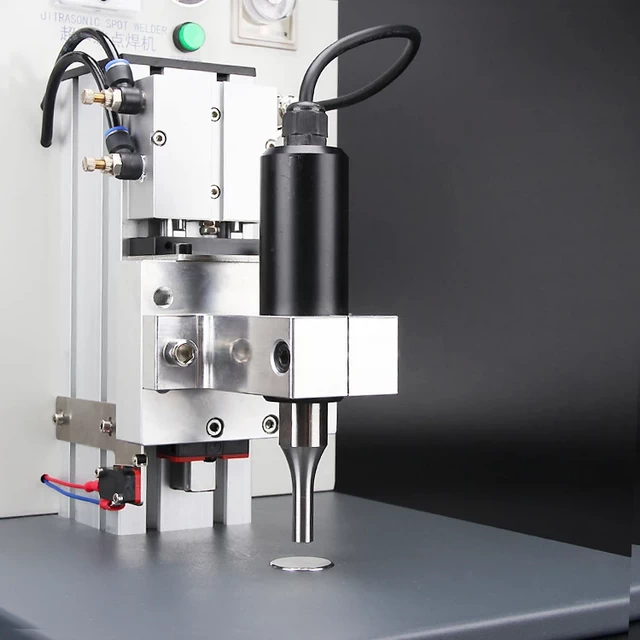

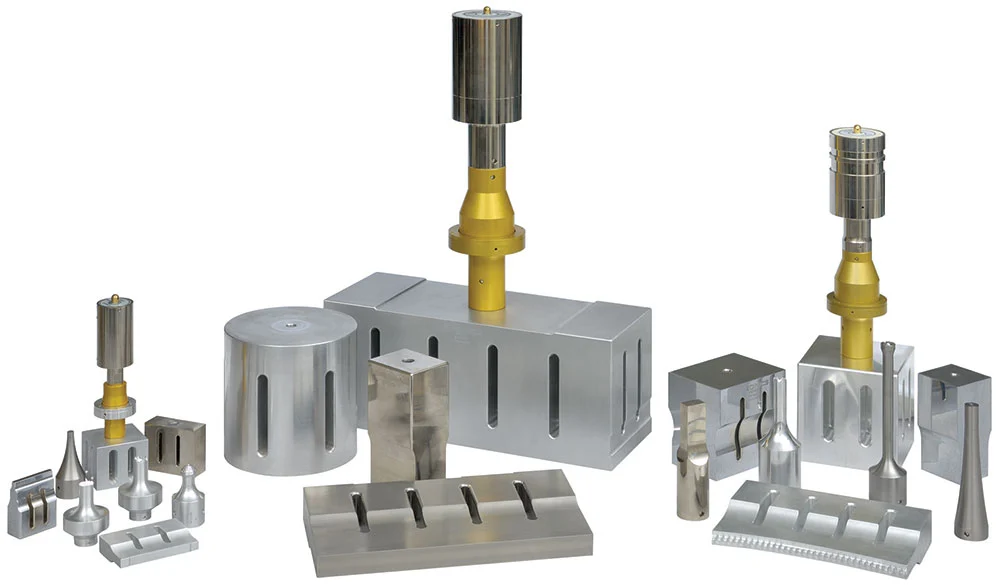

A complete ultrasonic welding system include various components. The active components generate the vibrations, transfer energy, and apply them into the welding joints. The passive components absorb the resulting forces, hold the parts in position, and particularly support the weld joint point at which the components are bonded together.

Active:

Ultrasonic generator

Converter

Amplitude transformer (booster or amplitude coupler)

Sonotrode (weld tool)

The converter, booster, and sonotrode are combined to form what is referred to as the stack.

Passive:

Fixture

Anvil

Process Technology: The Principle of Energy Focusing

In order to precisely melt the component, the vibration energy must be collected to converge on one point. Typically this is called as energy focusing. This specific point is where the heat exploring is strongest and melting occurs-for a defined welding process with very low energy consumption.

Types of Energy Focusing

Everything can be attributed to the question of shape: In order to make the vibration energy converge at the correct point, the geometry of the parts to be welded or the specific tools must be designed accordingly. For component-integrated focusing, energy directors (short for ED) focus the energy at the materials themselves. For energy focusing tool geometry, the tools are shaped for the specific application.

Frequently Asked Questions

Not found what you’re looking for?

In jointing design, the heating energy is focused by the shape of the components. Here, the area at where both parts are to be joined is given a specific shape. In most cases, there is an ultrasonic tip or an edge at this point. This is precisely in which the energy is focused, that is why these parts are called energy directors (Shorted for as).

The heating energy also can be focused by the welding tool. Here, the contour of the sonotrode acts as an aid to the ultrasonic melting process. The ultrasonic energy is focused at its tip, and this is where it becomes the hottest. This type of heating energy focusing is used for ultrasonic staking, for instance.

Here too, the shape of the fixture tool plays a crucial role. The anvil has heightened structures. These create contacting points with the components. These points are where the heating energy is focused, and leading to melting. This is used mostly for web material such as films and nonwovens, or cardboard packaging.

The Most Important Parameters For Ultrasonic Welding Process

Tight, sturdy, robust and visually appealing-to generate the perfect weld joint, the welding tool, material, and welding process must be well coordinated with each other. The Die settings are very critical: The right process parameters ensure optimal and reproducible results.

Faster than the human eyes can perceive, the welding tool vibrates with an amplitude between 5 and 50 μm. To get the required power, the mechanical vibration generated in the converter is changed by the amplitude transformer.

The ultrasonic (trigger) point defines the start of the welding: The sonotrode presses down on the component with the trigger force. If this only yields to a minimal extent over a specific period of time, the ultrasonics are triggered and the trigger force converts to weld force. This ensures that the start point of the welding always remains the same, and the quality of the results remains consistently high.

To ensure even and dense welding joints, the sound waves must hit the component with force. The extent of this force depends on the power, joining surface and size of the parts.

Joined in a flash: Once the trigger point has been reached and the ultrasonics are triggered, the actual welding process only lasts for split seconds. The weld time ends when a previously defined switch-off criterion is reached.

Once the welding time has ended, the components are basically kept under pressure. This allows them to cool down and firm up evenly. As the weld tool does not heat up throughout the entire process, it also supports the cooling process.

Which materials can be welded using ultrasonics?

Generally, most thermoplastic materials (plastics which can be shaped when heating is applied) can be welded with ultrasonics process. The harder the material, the better. In addition to plastics, different nonferrous metals such as aluminum, nickel, brass, and copper are also suitable for ultrasonic welding

Plastics

Whether industrial remote controllers, print cartridges or children’s toys,-many of our daily objects are made of plastic. To bond the parts safely, firmly and (if required) tightly together, they are sealed and joined using ultrasonic assembly.

Packaging

Food packing with ultrasonic process, the cheese can stay fresh and coffee will not lose its aroma. Thanks to ultrasonic sealing, food packaging is tightly encapsulated, and a saving is made on packaging material.Compared with traditional packing, this method protects the environment, and less food is wasted.

Nonwovens

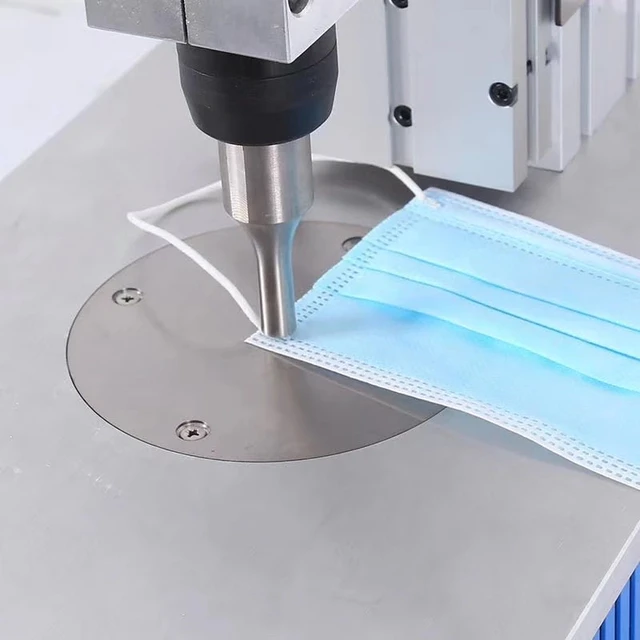

The using of ultrasonics in the field of non-woven fabrics is very effective: No heat-up phase, no use of adhesives, the cleaning intervals of the machines are shorted. Popular products from the business Unit NONWOVENS are surgical masks, diapers, cotton pads or various (feminine) hygiene products. Ultrasonics can be used to join, perforate, emboss or make precise cuts in nonwovens.

Metals

In the consumer and automotive products industries, the demand for lithium-ion batteries and plug-and-socket connections for cables has increased rapidly. Nonferrous metals such as aluminum and copper can be joined together using ultrasonic welding. Highest welding quality: Process visualization and process stability ensure product safety and reliability.