Documents Required to Quote or Order a PCB Assembly

What do you need to get a quote on a PCB assembly? This is a great question and often a source of confusion. There are four basic documents and exactly how they are transmitted depends on your company’s tools; we can work together to figure out what best fits your circumstance. Here we’ll explain what documents are necessary, as well as what information they should all contain, and their role in the quote process.

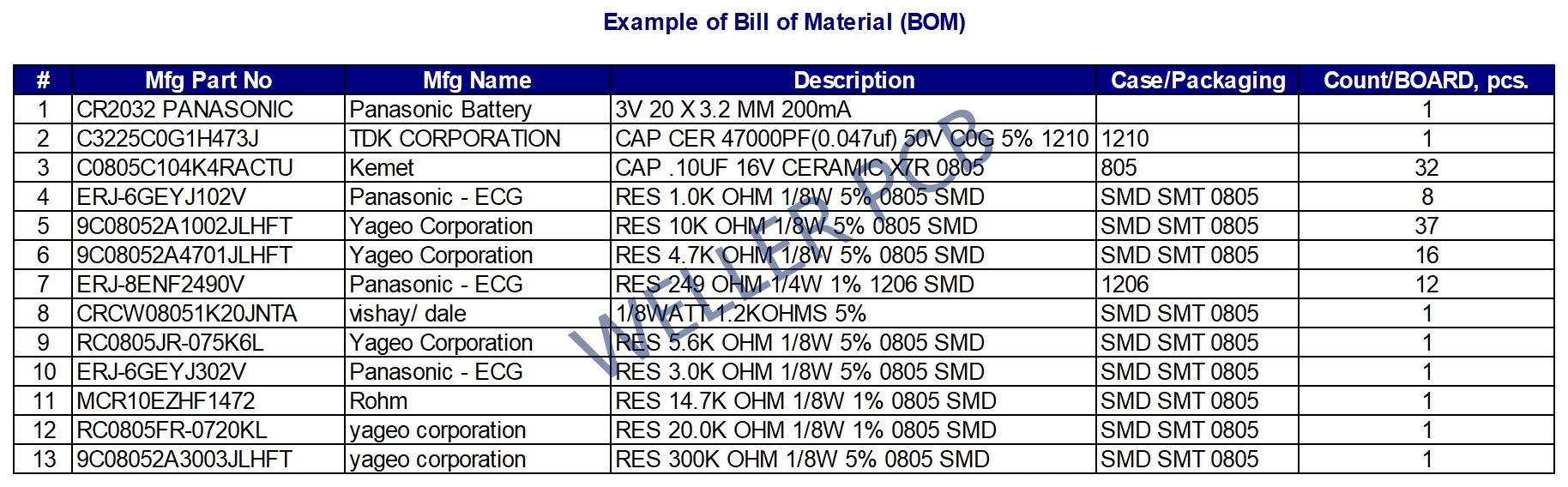

For PCBA inquiry please would you send us:

Your complete files will enable us to work effectively and timely saved in PCB Assembly Quotation.

For PCB Assembly Order please would you send us:

Your complete files will enable us to work effectively and timely saved in PCB Assembly Process.