Turnkey PCB Manufacturing

In today’s globalized economy, an increasing number of businesses are outsourcing some or all of their manufacturing to reliable third-party installers. With this growing demand, turnkey printed circuit board (PCB) manufacturing services are more important than ever. If you already count on WELLER for PCB or other electronic assembly services, make your assembly process completely turnkey by having us take over the box build stage, as well.

We are an ISO 9001:2015-registered company with extensive experience performing mechanical assembly for clients in demanding industries. Best of all, we are conveniently located in Shenzhen, south of China, and complete all work in-house. With our experienced engineering and technology in electronics manufacturing field, we are the ideal partner to global OEM or ODM clients.

What Is Box Building Assembly, and How Does It Relate to Turnkey PCB Fabrication?

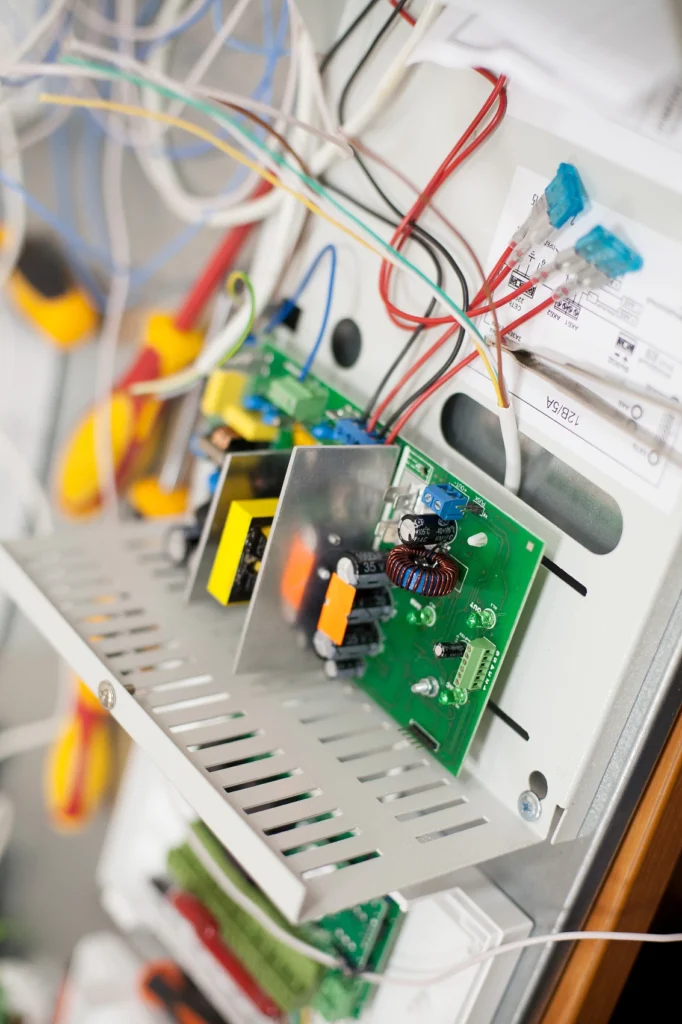

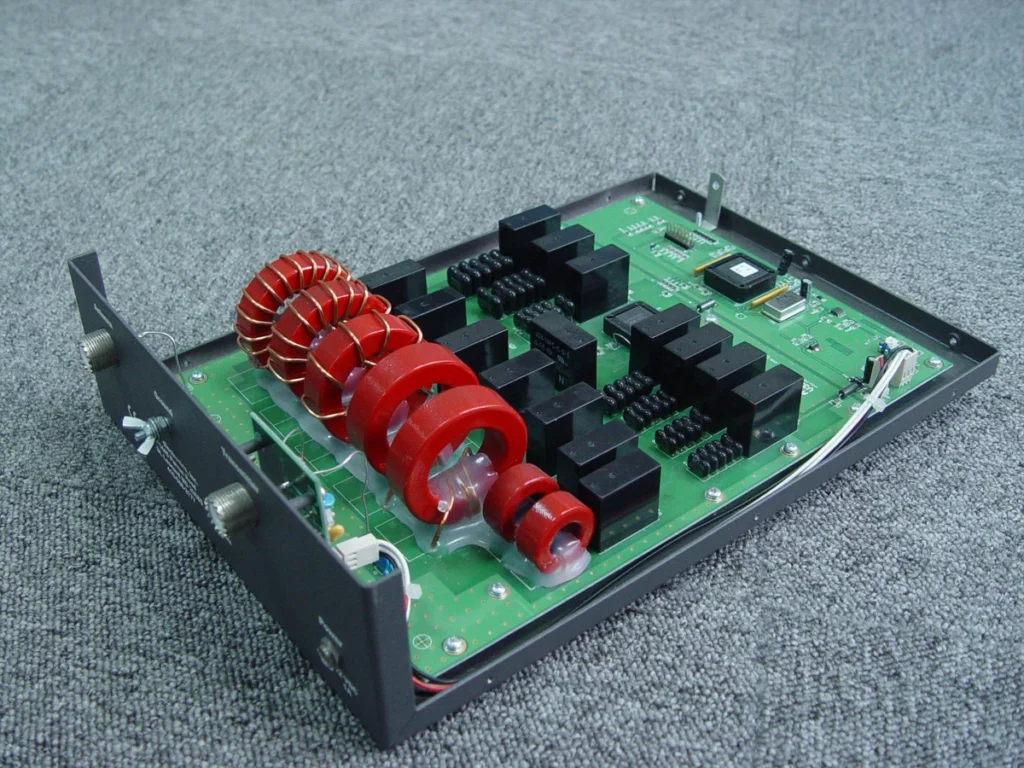

As a part of a total electronics manufacturing solution, box building assembly is another name for the mechanical systems integration phase of the electronics manufacturing process. Unlike the primary PCB assembly, where the manufacturer only builds and delivers populated printed circuit boards, a turnkey box building assembly goes the extra mile by putting the populated printed circuit board in a finished product.

This involves sourcing and installing wiring harnesses and cables, designing and installing any sub-assembly components, and embedding the whole package together in a customized enclosure. Other steps in a box building may refer software loading and system configuration, packaging and labeling, and more.

Additionally, the product may be subject to firmware burning-in or functional and final testing as part of the quality control process. Following a box building, the completed unit device may be drop-shipped directly to the customer or sent back to the manufacturer for additional packaging or testing.

What Is Included in a Box Building Assembly?

A box building assembly includes multiple services related to the electronics assembly and delivery of a final project. The services provided as part of a box building assembly depend on the supplier’s comprehensive capabilities and the client’s needs.

As a part of turnkey assembly solution, box building services cover the steps you need to complete between PCB assembly, testing and product delivery. Your box building assembly partner will design their process around your specifications and develop a custom solution that allows the work to meet your project goals.

An ideal electronic assembly partner may complete any of these tasks as part of a box build project:

Custom process that allows you to meet your project goals

How Is a Box Building Assembly Done?

Every box build assembly specifically involves a unique procedure that depends on the client’s requirements. To make sure your project requirements thoroughly to be performed, it is necessary to share your assembly partner with these documents:

Cable Assembly & Wire Harness Services

Cable assemblies and wire harness are basically the electrical delivery systems within and outside your box building. These are very critical components to a good result of box build, and they have a significant impact on the form, fit and function of your box build. Your assembly partner should have the ability of designing wire harness and cable assemblies with the right combination of materials for your specific project needs, so you get a solution that delivers optimal efficiency.

At WELLER, we have the tools, equipment and space necessary to offer quick turnarounds and stellar results. Work with the professionals at WELLER for reliable and quick cabling and wire harnessing services.

Benefits of Box Building Assembly Services

Performing electron-mechanical assembly services in-house requires dedicated staff, experienced technicians, and basic equipment, as well as adequate production space. Outsourcing the box build assembly of your product to WELLER is an excellent way of keeping overhead costs down while maintaining a high level of quality control. We are capable of turning around complex projects quickly, reducing your cycle times and bringing your product to market faster.

Working with WELLER will ultimately free up your internal resources to focus on product development, marketing exploring and other strategic plan. We strive to build mutual-trusted relationships with OEMs and suppliers through transparent communication. As an experienced box build assembly services facility based in Shenzhen, China, we can deliver all the benefits of outsourcing with saving in time and money.

How to Choose the Right Box Build Assembly Services

Once deciding to use underfill to handle the chips package, a series of challenges need to be taken into account to efficiently implement the process to achieve consistently reliable results while maintaining required mass production throughput levels. Some of key issues including:

Every electronics assembly house takes a different approach to the box building process. The right company for your project should have rich experience, advanced capabilities and related certifications to meet and exceed your requirements.

When searching for box building assembly services, consider these critical factors:

If you are a product design and sales company and look for a long-term professional and stable partner, consider WELLER for your box build assembly services. We provide turnkey box buildings for small to medium-batch projects.

Consider WELLER for your box building assembly services

The WELLER Box Building and PCB Assembly Process

At WELLER, we absolutely understand the importance of attention to detail for success in whole of electronic manufacturing process. From the start of each project to its final shipment, our dedicated team strives to raise the bar for quality and value in everything we do. As your reliable box building assembly partner, we will ensure that we deliver the exact results you expect. Our team has experience with quick-turn deliveries, specific drop shipments and other project delivery methods.

To show you a better idea about our services, consider the steps below we take to provide our clients with turnkey products ready to be installed:

Our Services

Our dedicated team specializes in all aspects of electron-mechanical assembly. If you have trusted professionalism on printed circuit board manufacturing and assembly, consider trusting us with additional aspects of the production cycle. Our facility is equipped with state-of-the-art assembly and testing equipment.

We offer total turnkey procurement of plastic and metal enclosures, wire harnesses and custom overlays. Custom packaging can range from complex point of sale packaging to bulk packaging. We are committed to ethical sourcing and manufacturing practices, and have implemented policies to eliminate conflict minerals in our supply chain.

Request a Free PCB Assembly Quote From WELLER

If you’re ready to benefit from PCB and box building assembly, it is worth to turn to WELLER. As an excellent provider of box build assembly services in China, we offer a superior commitment to high-quality products and customer satisfaction. Contact our sales online to see what we can do for you, and we’re proud to offer a diverse range of services, from prototyping all the way to high-volume production.

To know more about how our expertise can benefit your projects, reach out to receive a free quote. If you have any questions, you can also contact our sales online.