Al Technology-Electronic Design and Manufacturing

The integration of artificial intelligence (AI) in electronic manufacturing services has grown quickly in the industry. In PCB manufacturing, AI is used to carry out different tasks, and this has made the production process easier and more The integration of artificial intelligence (AI) in electronic manufacturing services has grown quickly in the industry. In PCB manufacturing, AI is used to carry out different tasks, and this has made the production process easier and more efficient, with reduced cost. This article covers the role of artificial intelligence in manufacturing high-performing PCB products.

Introduction

As industrial technology develops, artificial intelligence (AI) has become increasingly significant, specifically in the world of printed circuit board manufacturing and general electronics production. AI facilitates independent automation of PCB fabrication, using a wide range of data gathered from various sensors. This has consequently optimized the manufacturing process and product quality, whilst considerably reducing manufacturing costs. In essence, the introduction of AI in PCB manufacturing has served to improve efficiency and production yield.

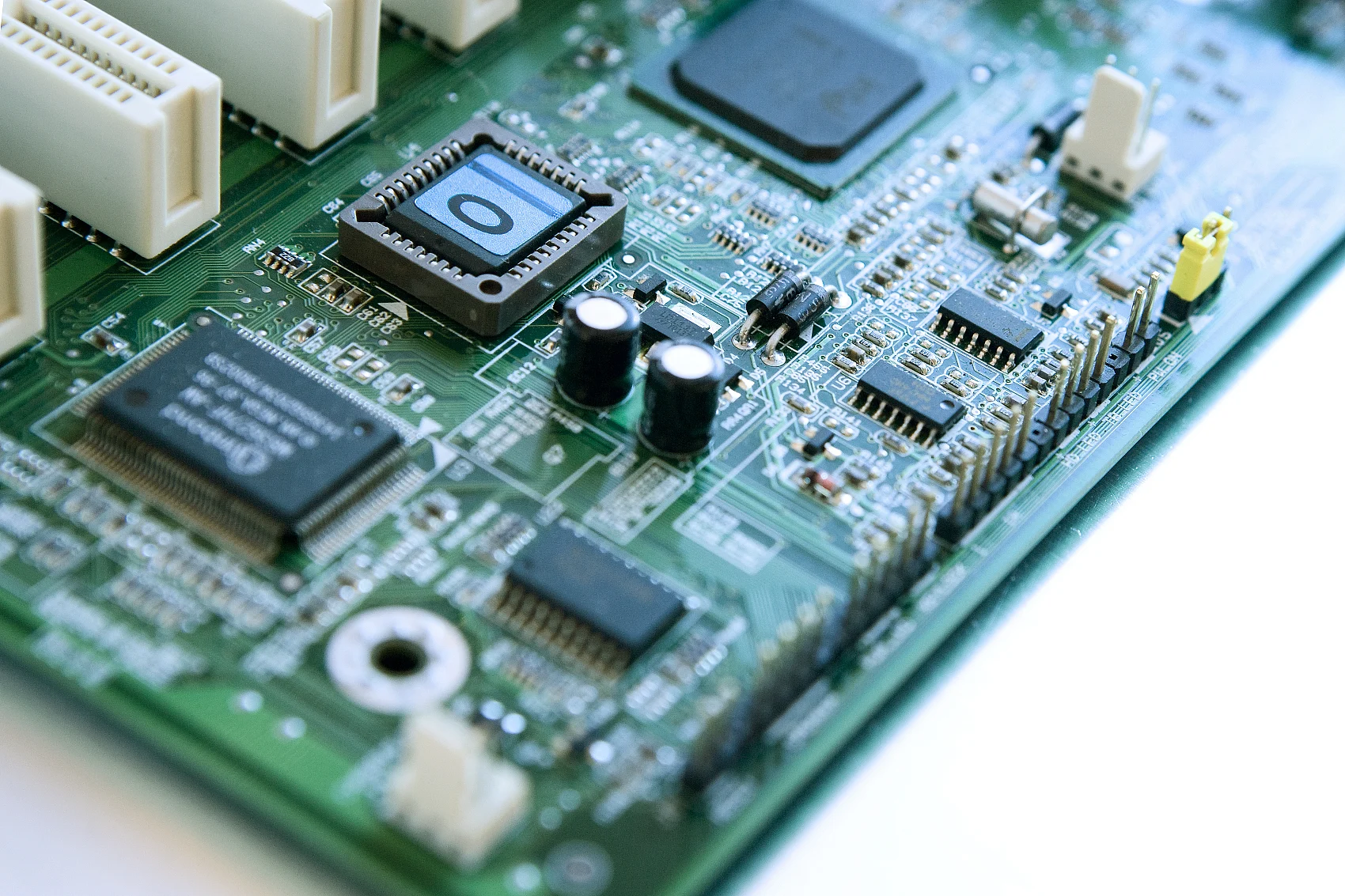

Artificial Intelligence in PCB Design

PCB designers use electronic design automation (EDA) tools in PCB circuit and layout designs. AI is integrated into these tools to streamline the process, making it faster and easier to design circuits accurately than regular computer programs.

Additionally, high-frequency signals on multi-layer PCBs can be routed effectively by AI-enabled auto-routers. They draw on human intelligence and learn from earlier design models.

AI is also applied for the validation of designs and error detection in PCBs. It can be used to evaluate different design versions and spot problems before production starts. AI can simulate intricate designs and systems, giving engineers the ability to spot possible problems before moving forward with the production stage.

Additionally, it can be used to provide design suggestions and offer immediate feedback on how well a design is working. This can assist engineers in making better decisions and enhance the general standard of their designs.

Artificial Intelligence in PCB Manufacturing

The implementation of AI across electronics manufacturing industries like PCB manufacturing has helped to fast-track requisite production processes and assembly services. It has also enhanced the quality of printed circuit boards with less cost, proving the advantageous impact of AI in PCB manufacturing.

The integration of AI in PCB manufacturing and assembly has been executed in various areas, in performing different essential tasks. They include the following:

PCB Testing and Inspection

AI-based PCB inspection is a growing trend. PCB 2D and 3D images are captured using sophisticated computer vision tools with machine learning capabilities. Using pattern recognition algorithms, the acquired image is compared to the reference image to identify mistakes.

It can be used to suggest remedial measures to enhance the quality of the product by quickly identifying and categorizing flaws, detecting defects, and finding possible failure reasons. AI may also be used to simulate and analyze PCBs more quickly and accurately, cutting down on the time and expense of manual testing and inspection while lowering the possibility of mistakes.

Routing

AI-infused routing algorithms can optimize the routing process by taking into account the size of the board, the type of components, and the number of layers. The algorithms are also capable of analyzing the design to determine the most effective route for the components while ensuring that there is enough room for additional components. Thus, fewer design adjustments may be necessary, and the routing procedure may go faster.

The procedure of allocating layers to each component can also be automated using AI. By employing algorithms that can quickly decide the appropriate layer for each component and then route the components accordingly, the required time to manually assign layers can be decreased, and the design can be enhanced for optimal performance.

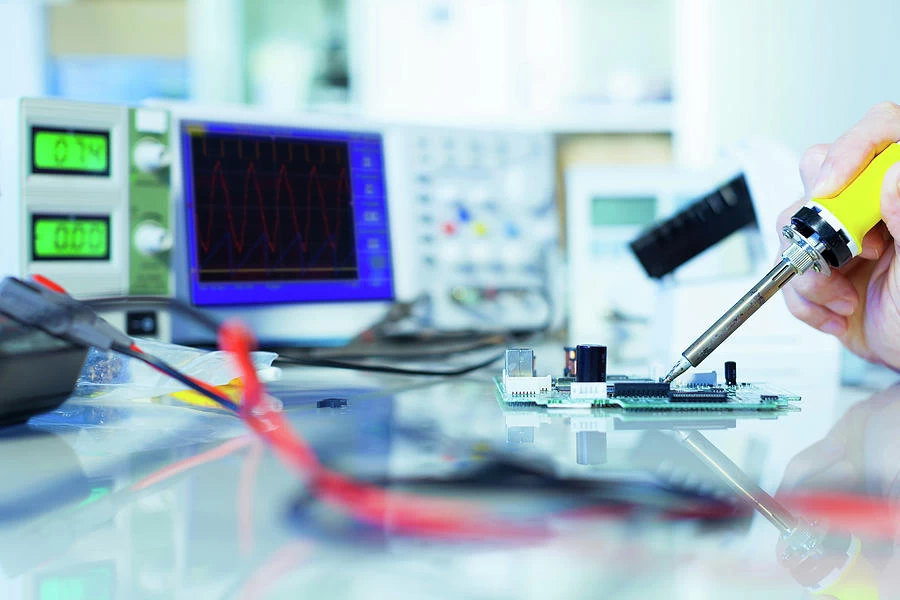

PCB Soldering

The nozzles on AI soldering machines help precisely solder tiny PCB components at a very high temperature. Additionally, they are highly productive in soldering fine-pitch integrated circuits (ICs).

Component Placement

AI algorithms can be used to determine the best locations for components on the PCB, as well as the most efficient paths for routing and the minimum number of components needed. As a result, the PCB design’s performance and reliability can be enhanced.

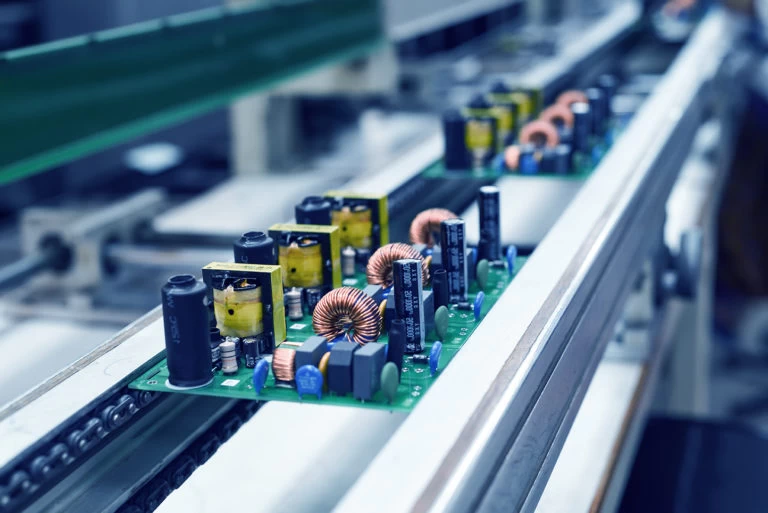

SMT Assembly

AI-powered automation of PCB assembly can help to cut down on the time and expense of a manual assembly line. AI can also assist in ensuring that the PCBs are appropriately assembled and that no mistakes are made, which can help to lower the likelihood of expensive reworks and production delays. It can instantly spot any issues or mistakes while monitoring the assembly process, allowing for quicker resolution and better product quality.

AI can be incorporated into PCB fabrication in different stages. Smart sensors are used to collect numerous data during the PCB fabrication process. The captured data is analyzed to pinpoint sections of the process flow that are prone to errors. This helps manufacturers make informed predictive decisions aimed at decreasing assembly line downtime and preventing losses.

Some benefits of AI in PCB design and manufacturing include:

Key Takeaways

An AI-enabled system collects vast amounts of data to be analyzed and interpreted using the sub-domains of machine learning and deep learning. The results of this analysis are used to improve PCB efficiency and production yield. AI also can provide troubleshooting support in real-time. All these data require expertise in AI and PCB manufacturing so that they can be applied to achieve the best results. In a custom PCB assembly factory, a competent AI operator can leverage the technology to manufacture quality and reliable printed circuit boards. You can find more about this at WellerPCB.