Standard 4L PCB Stack-up Design Reference

The standard 4L layers PCB stackup is the most common options selected by PCB designers. The standard layer stack-up structures can be utilized in most applications.

As a standard option, you can get a variable 4 layer stack up from us, which is defined by following parameters:

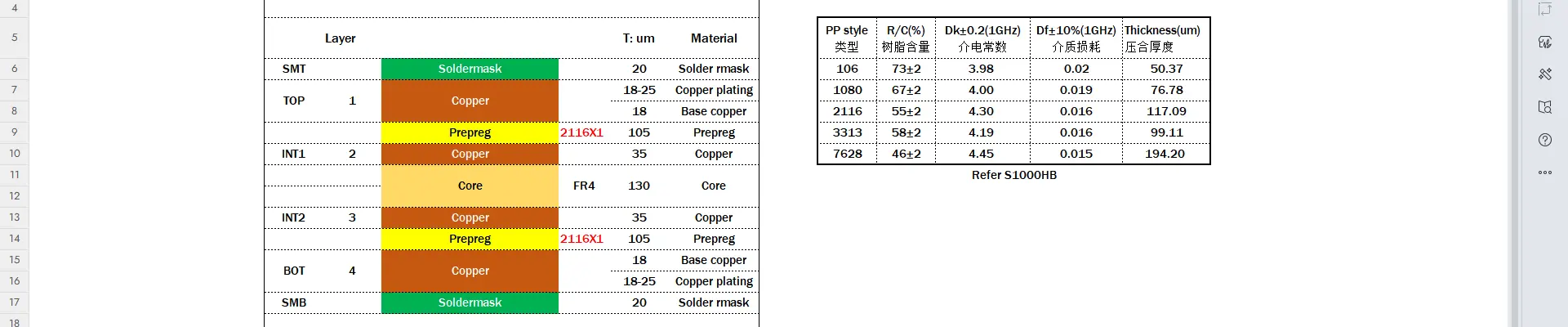

4L, T=0.50mm, 1/1/1/1oz

4L PCB Stack-Up T=0.50mm

| Layer | T: um | Material | |||||

| SMT | Soldermask | 20 | Solder rmask | ||||

| TOP | 1 | Copper | 18-25 | Copper plating | |||

| 18 | Base copper | ||||||

| Prepreg | 2116X1 | 105 | Prepreg | ||||

| INT1 | 2 | Copper | 35 | Copper | |||

| Core | FR4 | 130 | Core | ||||

| INT2 | 3 | Copper | 35 | Copper | |||

| Prepreg | 2116X1 | 105 | Prepreg | ||||

| BOT | 4 | Copper | 18 | Base copper | |||

| 18-25 | Copper plating | ||||||

| SMB | Soldermask | 20 | Solder rmask | ||||

| Finished PCB thickness: 0.5+/-0.10mm | |||||||

4L, T=0.80mm, 1/1/1/1oz

4L PCB Stack-Up T=0.80mm

| Layer | T: um | Material | |||||

| SMT | Soldermask | 20 | Solder rmask | ||||

| TOP | 1 | Copper | 18-25 | Copper plating | |||

| 18 | Base copper | ||||||

| Prepreg | 1080X1 | Prepreg | |||||

| 7628X1 | |||||||

| INT1 | 2 | Copper | 35 | Copper | |||

| Core | FR4 | 175 | Core | ||||

| INT2 | 3 | Copper | 35 | Copper | |||

| Prepreg | 7628X1 | Prepreg | |||||

| 1080X1 | |||||||

| BOT | 4 | Copper | 18 | Base copper | |||

| 18-25 | Copper plating | ||||||

| SMB | Soldermask | 20 | Solder rmask | ||||

| Finished PCB thickness: 0.8+/-0.10mm | |||||||

4L, T=1.00mm, 1/1/1/1oz

4L PCB Stack-Up T=1.00mm

| Layer | T: um | Material | |||||

| SMT | Soldermask | 20 | Solder rmask | ||||

| TOP | 1 | Copper | 18-25 | Copper plating | |||

| 18 | Base copper | ||||||

| Prepreg | 1080X1 | Prepreg | |||||

| 7628X1 | |||||||

| INT1 | 2 | Copper | 35 | Copper | |||

| Core | FR4 | 440 | Core | ||||

| INT2 | 3 | Copper | 35 | Copper | |||

| Prepreg | 7628X1 | Prepreg | |||||

| 1080X1 | |||||||

| BOT | 4 | Copper | 18 | Base copper | |||

| 18-25 | Copper plating | ||||||

| SMB | Soldermask | 20 | Solder rmask | ||||

| Finished PCB thickness: 1.00+/-0.10mm | |||||||

4L, T=1.60mm, 1/1/1/1oz

4L PCB Stack-Up T=1.60mm

| Layer | T: um | Material | |||||

| SMT | Soldermask | 20 | Solder rmask | ||||

| TOP | 1 | Copper | 18-25 | Copper plating | |||

| 18 | Base copper | ||||||

| Prepreg | 1080X1 | Prepreg | |||||

| 7628X1 | |||||||

| INT1 | 2 | Copper | 35 | Copper | |||

| Core | FR4 | 930 | Core | ||||

| INT2 | 3 | Copper | 35 | Copper | |||

| Prepreg | 7628X1 | Prepreg | |||||

| 1080X1 | |||||||

| BOT | 4 | Copper | 18 | Base copper | |||

| 18-25 | Copper plating | ||||||

| SMB | Soldermask | 20 | Solder rmask | ||||

| Finished PCB thickness: 1.60+/-0.16mm | |||||||

4L, T=2.00mm, 1/1/1/1oz

4L PCB Stack-Up T=2.00mm

| Layer | T: um | Material | |||||

| SMT | Soldermask | 20 | Solder rmask | ||||

| TOP | 1 | Copper | 18-25 | Copper plating | |||

| 18 | Base copper | ||||||

| Prepreg | 1080X1 | Prepreg | |||||

| 7628X1 | |||||||

| INT1 | 2 | Copper | 35 | Copper | |||

| Core | FR4 | 1530 | Core | ||||

| INT2 | 3 | Copper | 35 | Copper | |||

| Prepreg | 7628X1 | Prepreg | |||||

| 1080X1 | |||||||

| BOT | 4 | Copper | 18 | Base copper | |||

| 18-25 | Copper plating | ||||||

| SMB | Soldermask | 20 | Solder rmask | ||||

| Finished PCB thickness: 2.00+/-0.20mm | |||||||

4L, T=2.50mm, 1/1/1/1oz

4L PCB Stack-Up T=2.50mm

| Layer | T: um | Material | |||||

| SMT | Soldermask | 20 | Solder rmask | ||||

| TOP | 1 | Copper | 18-25 | Copper plating | |||

| 18 | Base copper | ||||||

| Prepreg | 1080X1 | Prepreg | |||||

| 7628X1 | |||||||

| INT1 | 2 | Copper | 35 | Copper | |||

| Core | FR4 | 1930 | Core | ||||

| INT2 | 3 | Copper | 35 | Copper | |||

| Prepreg | 7628X1 | Prepreg | |||||

| 1080X1 | |||||||

| BOT | 4 | Copper | 18 | Base copper | |||

| 18-25 | Copper plating | ||||||

| SMB | Soldermask | 20 | Solder rmask | ||||

| Finished PCB thickness: 2.50+/-0.25mm | |||||||

4L, T=3.00mm, 1/1/1/1oz

4L PCB Stack-Up T=3.00mm

| Layer | T: um | Material | |||||

| SMT | Soldermask | 20 | Solder rmask | ||||

| TOP | 1 | Copper | 18-25 | Copper plating | |||

| 18 | Base copper | ||||||

| Prepreg | 1080X1 | Prepreg | |||||

| 7628X1 | |||||||

| INT1 | 2 | Copper | 35 | Copper | |||

| Core | FR4 | 2330 | Core | ||||

| INT2 | 3 | Copper | 35 | Copper | |||

| Prepreg | 7628X1 | Prepreg | |||||

| 1080X1 | |||||||

| BOT | 4 | Copper | 18 | Base copper | |||

| 18-25 | Copper plating | ||||||

| SMB | Soldermask | 20 | Solder rmask | ||||

| Finished PCB thickness: 3.00+/-0.30mm | |||||||

Above stack-up options is our standard 4L layer PCB buildup that upon the best manufacturing features: such as below for finished thickness 1.60mm with 2/2/2/2 oz 4L PCB stack-up, option 1 is not so good as option 2 (because prepreg 1080 in option 2 has more glue than 7268 in option 1, therefore which can have a better bonding performance with core when it comes to laminate pressing process):

4L, T=1.60mm, 2/2/2/2oz, Option 1

4L PCB Stack-Up T=1.60mm, 2/2/2/2oz, Option-1

| Layer | T: um | Material | |||||

| SMT | Soldermask | 20 | Solder rmask | ||||

| TOP | 1 | Copper | 25-35 | Copper plating | |||

| 35 | Base copper | ||||||

| Not the best option | Prepreg | 7628X1 | Prepreg | ||||

| 7628HX1 | |||||||

| INT1 | 2 | Copper | 70 | Copper | |||

| Core | FR4 | 460 | Core | ||||

| INT2 | 3 | Copper | 70 | Copper | |||

| Not the best option | Prepreg | 7628HX1 | Prepreg | ||||

| 7628X1 | |||||||

| BOT | 4 | Copper | 35 | Base copper | |||

| 25-35 | Copper plating | ||||||

| SMB | Soldermask | 20 | Solder rmask | ||||

| Finished PCB thickness: 1.60+/-0.16mm | |||||||

4L, T=1.60mm, 2/2/2/2oz, Option 2

4L PCB Stack-Up T=1.60mm, 2/2/2/2oz, Option-2

| Layer | T: um | Material | |||||

| SMT | Soldermask | 20 | Solder rmask | ||||

| TOP | 1 | Copper | 25-35 | Copper plating | |||

| 35 | Base copper | ||||||

| The best option | Prepreg | 1080 (RC 60%) | 76 | Prepreg | |||

| 7628 (RC 48%) | 220 | ||||||

| INT1 | 2 | Copper | 70 | Copper | |||

| Core | FR4 | 830 | Core | ||||

| INT2 | 3 | Copper | 70 | Copper | |||

| The best option | Prepreg | 7628 (RC 48%) | 220 | Prepreg | |||

| 1080 (RC 60%) | 76 | ||||||

| BOT | 4 | Copper | 35 | Base copper | |||

| 25-35 | Copper plating | ||||||

| SMB | Soldermask | 20 | Solder rmask | ||||

| Finished PCB thickness: 1.60+/-0.16mm | |||||||

Above stack-up options is our standard 4L layer PCB buildup with 2/2/2/2 oz final finished copper thickness that already upon the best manufacturing features for multi-layer PCBs, they are common and suitable for most PCB design.

If you specifically need a customized multi-layer PCB stack-up or any buildup with impedance control, or you need a specific PCB stack-up with 2oz or upper copper thickness, you can send your request to service@wellerpcb.com. Our engineer will have a professional response with 2-4 hours.

Shengyi Prepreg S1000HB Reference

Based Material Line Up S1000H (S1000HB)-PREPREG (B-STAGE)

| Glass style | RC (%) Nominal | Thickness | Dk | Df | |||||||

| mm | mil | 1GHz | 3GHz | 5GHz | 10GHz | 1 GHz | 3 GHz | 5 GHz | 10 GHz | ||

| 7628 | 43* | 0.185 | 7.28 | 4.81 | 4.74 | 4.74 | 4.73 | 0.014 | 0.015 | 0.015 | 0.016 |

| 7628 | 46 | 0.195 | 7.68 | 4.74 | 4.68 | 4.66 | 4.66 | 0.015 | 0.016 | 0.016 | 0.016 |

| 7628 | 48 | 0.205 | 8.07 | 4.70 | 4.63 | 4.61 | 4.61 | 0.015 | 0.016 | 0.016 | 0.017 |

| 7628 | 50 | 0.215 | 8.46 | 4.65 | 4.58 | 4.57 | 4.57 | 0.016 | 0.016 | 0.017 | 0.017 |

| 7628 | 52 | 0.225 | 8.86 | 4.59 | 4.52 | 4.51 | 4.50 | 0.016 | 0.016 | 0.017 | 0.017 |

| 1506 | 48 | 0.160 | 6.30 | 4.70 | 4.63 | 4.61 | 4.61 | 0.015 | 0.016 | 0.016 | 0.017 |

| 1506 | 50 | 0.170 | 6.69 | 4.65 | 4.58 | 4.57 | 4.57 | 0.016 | 0.016 | 0.017 | 0.017 |

| 1506 | 52 | 0.180 | 7.09 | 4.59 | 4.52 | 4.51 | 4.50 | 0.016 | 0.016 | 0.017 | 0.017 |

| 2116 | 52* | 0.113 | 4.45 | 4.59 | 4.52 | 4.51 | 4.50 | 0.016 | 0.016 | 0.017 | 0.017 |

| 2116 | 53* | 0.116 | 4.57 | 4.57 | 4.50 | 4.49 | 4.48 | 0.016 | 0.017 | 0.017 | 0.018 |

| 2116 | 55 | 0.120 | 4.72 | 4.53 | 4.45 | 4.43 | 4.43 | 0.017 | 0.017 | 0.018 | 0.018 |

| 2116 | 58 | 0.130 | 5.12 | 4.45 | 4.38 | 4.36 | 4.36 | 0.017 | 0.018 | 0.018 | 0.018 |

| 3313 | 57 | 0.100 | 3.94 | 4.48 | 4.41 | 4.39 | 4.39 | 0.017 | 0.018 | 0.018 | 0.018 |

| 1080 | 65 | 0.072 | 2.83 | 4.29 | 4.21 | 4.19 | 4.18 | 0.019 | 0.019 | 0.019 | 0.020 |

| 1080 | 68 | 0.081 | 3.19 | 4.21 | 4.13 | 4.11 | 4.11 | 0.020 | 0.019 | 0.020 | 0.020 |

| 1080 | 70 | 0.087 | 3.43 | 4.16 | 4.08 | 4.05 | 4.05 | 0.020 | 0.019 | 0.020 | 0.020 |

| 106 | 73 | 0.050 | 1.97 | 4.09 | 4.01 | 3.97 | 3.97 | 0.020 | 0.020 | 0.020 | 0.020 |

| 106 | 78 | 0.063 | 2.14 | 3.97 | 3.89 | 3.83 | 3.83 | 0.02 | 0.021 | 0.020 | 0.022 |

| Remark: | |||||||||||

| 1) Test by SPDR method. | |||||||||||

| 2) The data above show actual values and are not guaranteed, for your reference only. | |||||||||||

| 3) RC* is not common type for reference. | |||||||||||

| 4) Last update: Oct, 2020 | |||||||||||