How to understand the difference between 2-layer and multi-layer PCB

When it comes to talk about PCBs (printed circuit boards), nearly it is impossible to get a fixed answer that how many layers you can have. Some IC test mainboards even have nearly a hundred layers in their construction; but, the most consuming electronic products only have common layer count PCBs usually from two to four layers. From this blog article reference, you will find out what the differences are and how you can get an informed answer for your next electronic project.

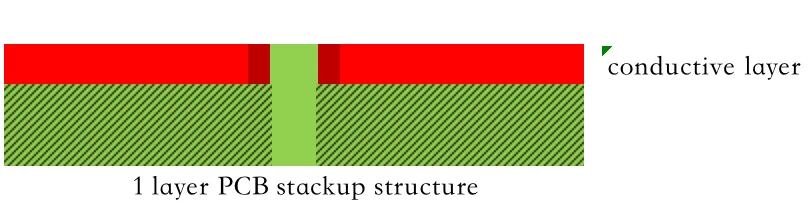

Single-Layer PCBs

Compared to 2-layer PCBs, single-layer PCBs are really much easier to work with due to their simple design. Why we think it is so simple is due to that they only have 1 layer conductive layer and with necessary tooling holes, no through via holes for conductive purpose. This feature determine that it’s PCB manufacturing process is very simplicity and cost is very low accordingly. The universal application of the single -layer PCBs is in switch power supply. You can find more details about single sided PCB blog.

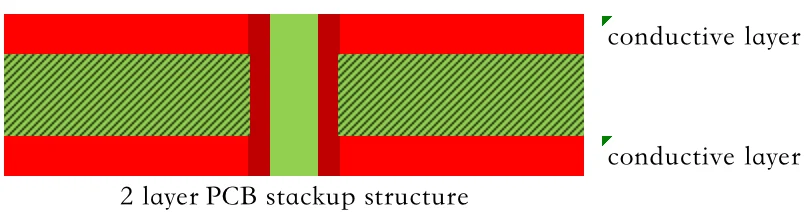

2-Layer PCBs

Compared to 1-layer PCBs and 4-layer PCBs, 2-layer circuit boards are a little bit more complex than single sided PCB but simple than 4-layer PCBs. Double-sided circuit board contain just a single layer of the base dielectric substrate. However, they contain conductive layers on both top and bottom side. Their advantage is that you can directly get double-side input without sacrificing the functionality. And, it’s reduced complexity leads to an equally reduced cost level, but this means there are fewer possibilities than with the 4-layer PCB. As a pro, though, there is no transmission delay with the signal.

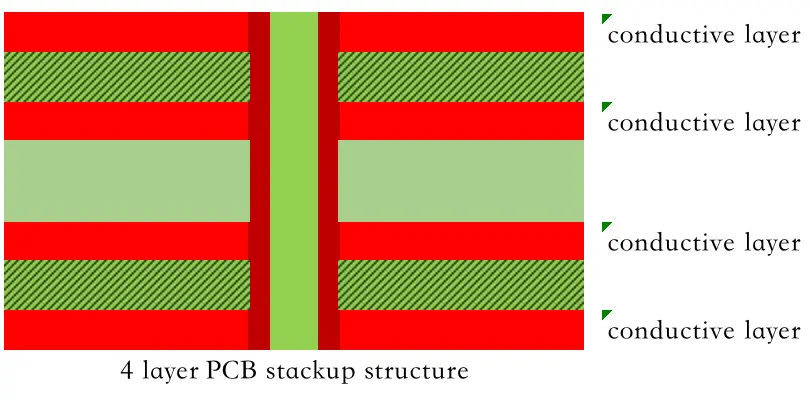

4-Layer PCBs

4-layer PCBs have much more conductive layer than a 2-layer PCB, increasing the possibilities accordingly. So as that they can be great for more complex electronic devices. Because it’s complexity feature, the production cost will be higher and the development will be a bit longer. More or less they are also more likely to have some propagation delays, so be sure to factor in extra production time to any project timeline.

What are the PCB Layers Used For?

The most important layer in a printed circuit board is the copper signal layer, which is what the PCBs are named after.

Normally 2-layer PCBs have two signal layers, but not the same computing that the 4-layer PCBs do not have four signal layers, normally they have 3 layers signal layers with 1 layer used for power ground purpose. The signal layers are used to connect to other electronic components in the electronic device. In between those layers is the insulation layer or dielectric core, which is added in between the signal layers to give it structure properly.

In 4-layer PCBs, here’s also the solder mask layer, which is applied above the signal layers. This is to prevent the copper traces from interfering with other metal components on the PCB board. They also have a silkscreen layer which is used to add designation to the different components, making them easier to be understood.

If you’re looking for high quality PCB solutions, look no further than Weller Technology. We offer one stop solution to electronic product from PCB layout, PCB prototypes, PCB fabrication, PCB assembly, electronics components sourcing as well. Our 24-hour tech support team would love to help you– contact us today.