PCB surface finishing technology

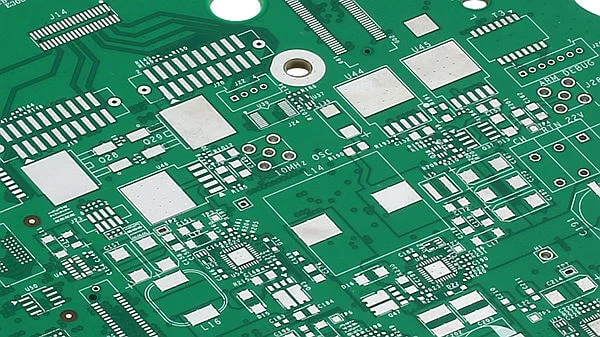

When surface finish (also called surface coating) defined to a PCB it means an intermetallic joint between the exposed bare copper of the solder-able area of the circuit board and the electronic components, this excluding the area of solder mask. Printed circuit boards without a protective coating would be susceptible to oxidation, therefore the requirement of the surface finish.

The application purpose of surface finishing

The core application of surface finishing

Two common types of surface finishing

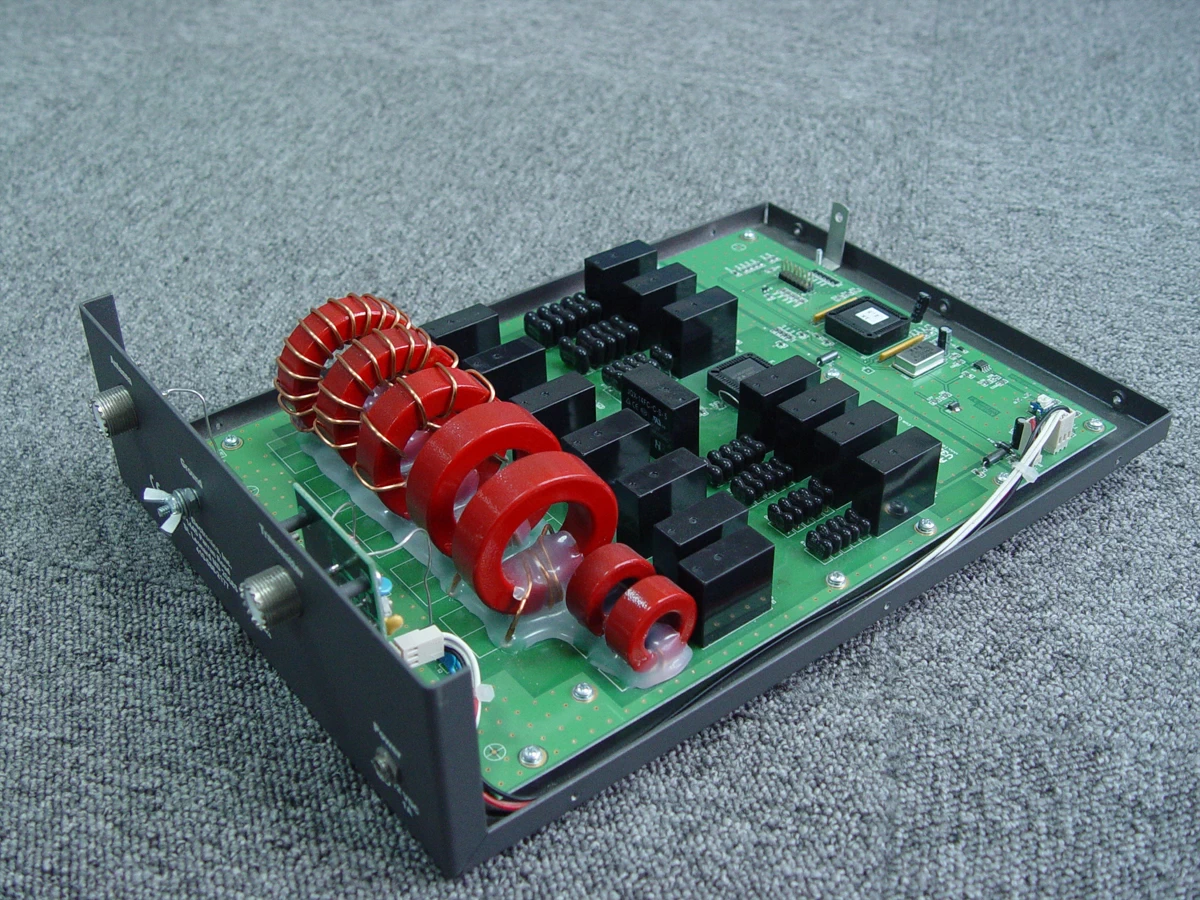

HAL (or HASL)

This is to drop the PCB into a batch of molten Sn/Pb solder so that all the exposed cooper to be covered and excess solder is moved by passing the PCB between 230℃ hot air knives.

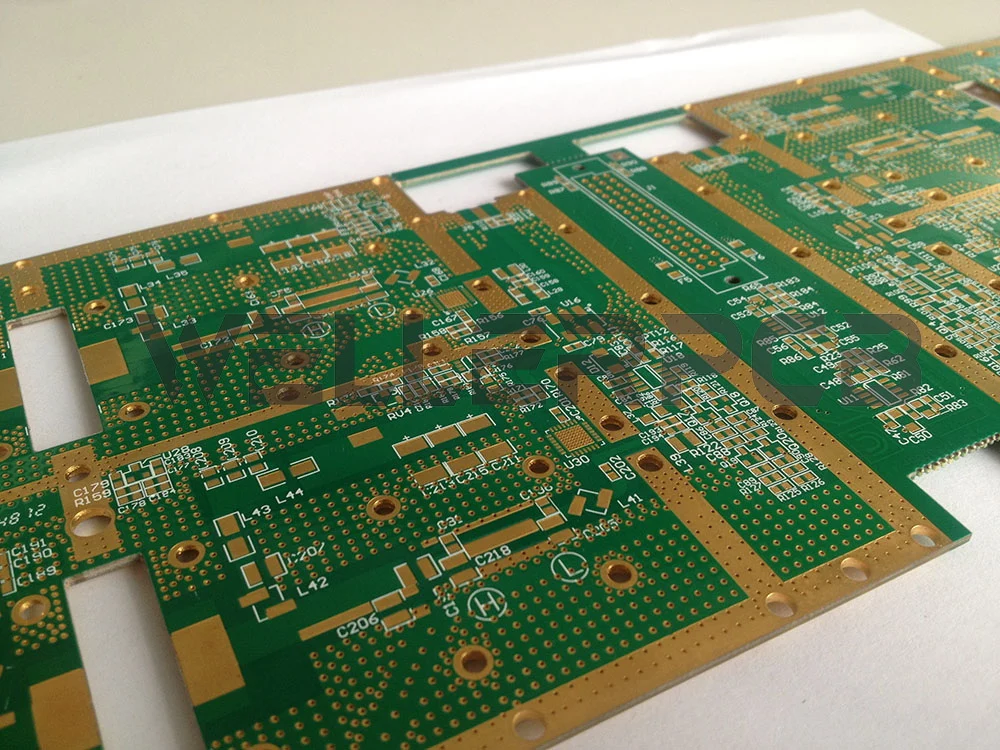

ENIG: Electroless Nickel Immersion Gold

Chemical Ni/Au refers to electroless Ni plating (thickness ≥3um) on the exposed PCB connection pad and then plating a layer of 0.05-0.15um thin gold over it, or plating a layer of thick gold (0.3-0.5um). Due to the chemical plating layer has very good feature of evenness, perfect smooth surface, and can provide multiple welding performances and the low contact resistance, therefore ENIG is mostly preferred by PCB assemblers due to it’s high electrical conductivity.