Making an Informed Choice for Electronic Protection

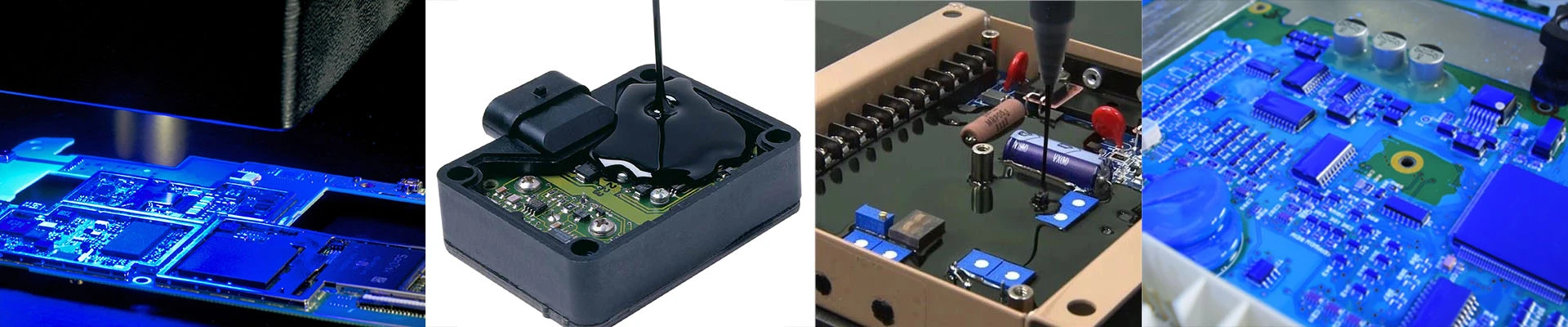

Today the electronics industry is one of the most rapidly expanding industries in the world, with an almost unlimited range of applications. more and more printed circuit boards (PCBs) are found in many domestic, industrial, automotive and military devices and require protection from their environment. Even it is perfectly PCB fabrication, Lack of protection can lead to reduced performance or in the worst case, complete failure. Protection can be offered in the form of conformal coatings or potting and encapsulation resins. Here at Weller, a question that is often asked is:

“Which Way is Better Option to Protect my PCBA, Conformal Coating or Potting Resin?”

But it would be a bit pity as there is no a fixed good answer to this question,actually it depends on the degree of environmental protection required to the PCB assembly devices. The first option for consideration is often the design of any housing within which the PCBA board will be enclosed. If an assembled PCB board is enclosed in a housing which is designed to be the primary environmental protection, then a conformal coating is often used to provide a back-up to the primary protection provided by the housing. But where once the housing case is not suitable or capable of providing primary protection of the PCB assembly from its operating environment, then most times a resin protection might be a better option.

The next interesting question should then be:

“What is a coating,and what is a resin?”

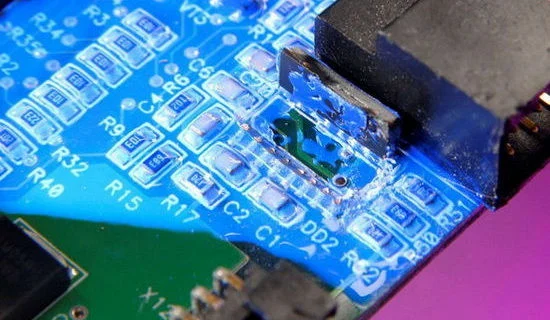

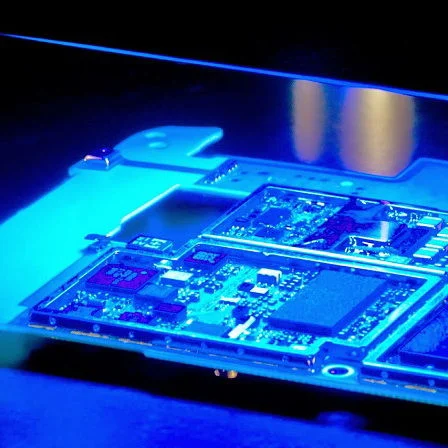

Conformal coating is a protective coating or polymer film 25-75µm thick (50µm typical and up to 100um) that ‘conforms’ to the circuit board topology. Its purpose is to protect electronic PCB board from harsh environments that may contain high humidity, a range of airborne contaminants and varying temperatures.We can offer conformal coating service with material DCA200H & AFA20

Potting resin is a process of filling a complete electronic assembly PCB board by a solid or gel compound for resistance to shock and vibration, and for exclusion of moisture and corrosive agents. Our range of potting compounds and encapsulants includes epoxy, polyurethane and silicone chemistries, to provide for every application. We can offer potting resin service with material resin 3M-DP270,and EPIC S7302.

Making an Informed Choice – Which do I Choose?

If we look at both’s features, then we can consider what features is common between the two, both are generally organic polymers, which can cure to form an electrically insulating layer that provide some degree of chemical and thermal resistance. There is a degree in commonality in the chemistry of the polymers used, with acrylic, epoxy, polyurethane and silicone being the most often encountered.

Below table would be a good reference for your choice of protecting your PCB assembly board.

Potting resins in PCB electronic assembly

| Item | Conformal Coating | Resin/Potting |

| Protection | - | + |

| Weight | + | - |

| Cost | + | - |

| Thermal Managment | + | - |

| Rework | + | - |

| Strees | + | - |

So,you can choose your protection material for your PCB assembly board by your global analysis to your final product application.

Any more concerning or questions,you can reach us by service@wellerpcb.com.