How 5G Technology Can Impact The Electronics Manufacturing Industry

The 5G network has emerged as a boon for the electronics industry. The manufacturers who previously used 4G for connecting various machines on the factory floor can now perform the same tasks faster with 5G. Besides, there is the added advantage of higher reliability and better quality of the end products.

5G has the potential to create new possibilities for electronic manufacturers as it allows them access to data and automation to take their operations to the next level.

Manufacturers can use the 5G technology to take advantage of various emerging opportunities. With its assurance of faster speeds, lower latency, and more capacity to networks, 5G has the ability to create new opportunities for the electronics manufacturing industry.

Speed Can Result In Enhanced Productivity

The most notable benefit of 5G is increased speed. Everyone relates this technology to lightning speed, and they are not off the mark. Theoretically, at least 5G is ten times faster than 4G. In practice, too, it will most likely match this claim.

5G will allow businesses to handle massive volumes of data quickly and effortlessly. By using 5G, electronics manufacturers can download design files faster. It can help cut down product development cycles drastically. They will also be able to monitor production lines in real-time. It can help zero in on the problem and solve them faster than before.

More Capacity Creates Opportunities To Explore New Markets

5G networks are designed to provide significantly more capacity than any previous generation of wireless technology. Devices can instantly connect to the 5G network without falling in performance. Electronic manufacturers can use this 5G feature to add more machines to their production lines. The network will also have additional capacity for handling cameras and sensors.

Apart from boosting efficiency and improving productivity, the 5G network will also allow manufacturers to perform detailed and accurate analytics as they can access more data at a faster pace. With access to analytics and enhanced capacity, manufacturers can explore newer technologies and improve the quality of their products and customer support.

Superior Quality Control Through Enhanced Latency

5G is synonymous with low latency-the time a data packet takes to travel from the source host to the server and back to the host. Low latency translates into superior control. This is a key feature for applications that need quick responses. Electronics manufacturers can closely watch production lines in real time with 5G. Any change required can be quickly introduced to boost quality control.

5G networks is, without doubt, a big boon to the electronics manufacturing services industry as it helps achieve incredible speeds, offer huge capacities, superior control over all aspects but especially on quality, and lower latency. All these factors are guaranteed top to boost efficiency and improve productivity in the manufacturing process.

5G technology is poised to dramatically change our lifestyle with its reliable connections and superfast download speed. Make sure you are fully prepared to embrace and explore the 5G network and take advantage of the numerous opportunities it will present.

PCB Manufacturing and Assembly in 5G

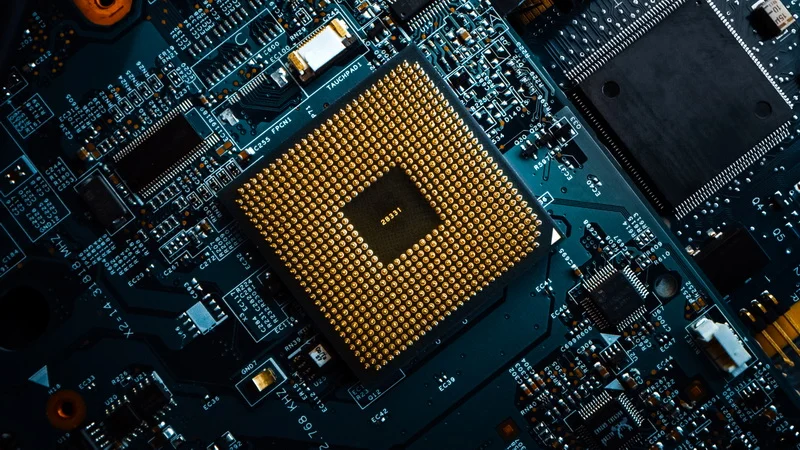

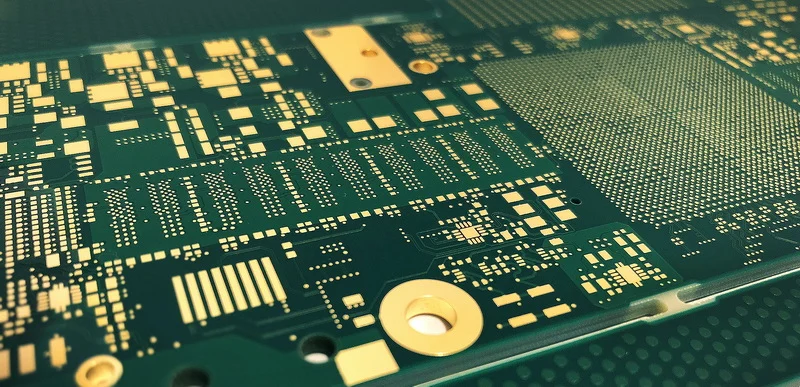

Due to 5Gs high frequency, high speed transferring features, it has greatly impacted various electronics design and manufacturing aspects, such as PCB design, circuit board assembly.

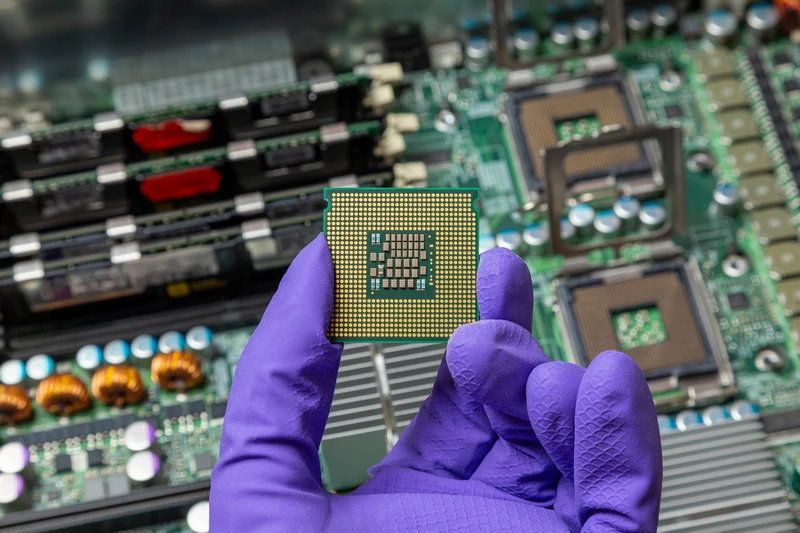

Most 5G devices use HDI printed circuit boards with fine circuit track/spacing, high density pad design, limited tolerance to impedance control. Therefore, PCB manufacturers must have to incorporate sophisticated technology and advanced manufacturing equipment.

Meantime, due to numerous components and fine pitch integrated circuits loaded on the printed circuit board, it require the 5G PCB assembly more complex and high precision machines in soldering paste printing, solder printing inspection, SMT assembly, 10+ multi-temperature zone reflow machine, AOI and X-ray inspection. The full manufacturing and assembly loop must be in high precision process to avoid any potential failure and reduce the defect ratio.