Most of new PCB designers have questions and confusion on the stiffeners when work on a flexible PCB design, below let’s talk more about the flex circuits stiffeners.

What is flex circuits Stiffeners?

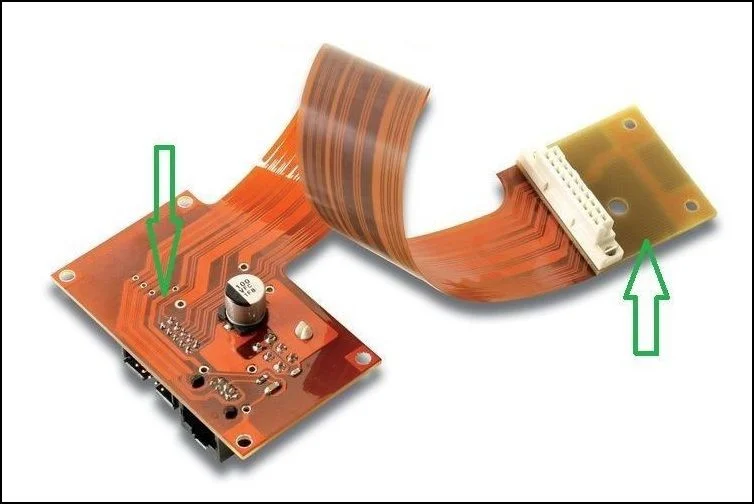

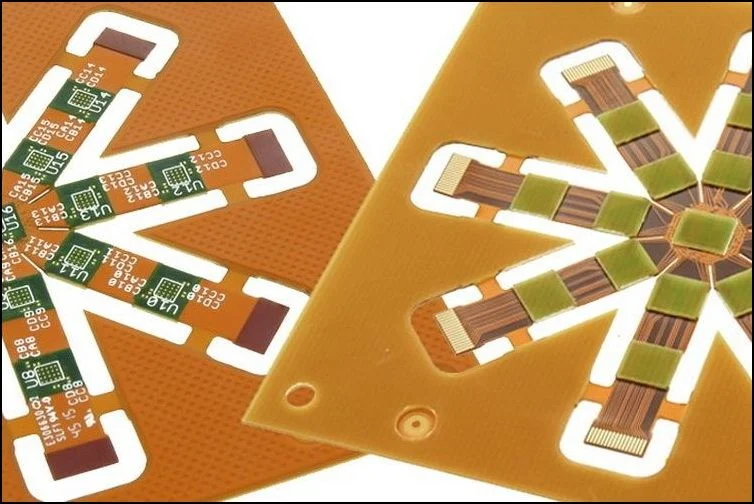

Stiffeners are a type of material which added to a flex circuit to rigidize some particular zones on the flex PCB board. Normally, rigidizing is recommended to apply to the zones under the back side of SMD components soldering to ensure a good assembly quality of flex PCB soldering.

Flexible PCB stiffener’s common usage application:

Component or Connector Stiffeners

Function:

Material Options:

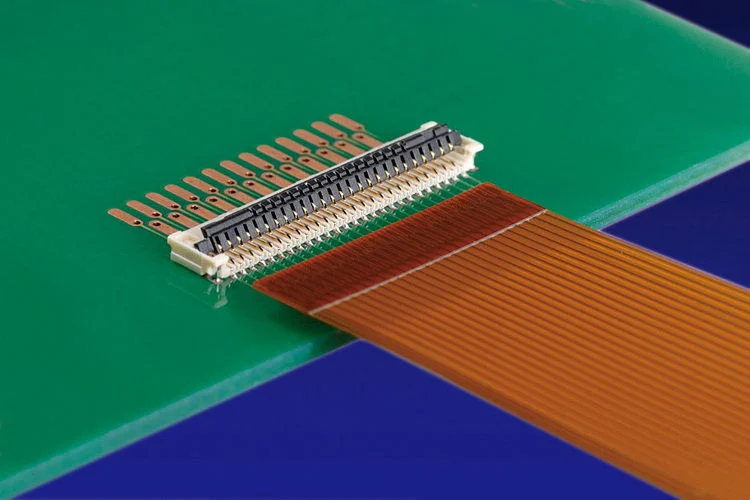

ZIF Stiffeners

Function:

Material Options:

Localized Bend Constraints Stiffeners

Function:

Material Options: