Silkscreen is one of important compositions to a complete PCB board fabrication, especially it’s high importance to finally circuit board assembly.

What is the PCB Silkscreen?

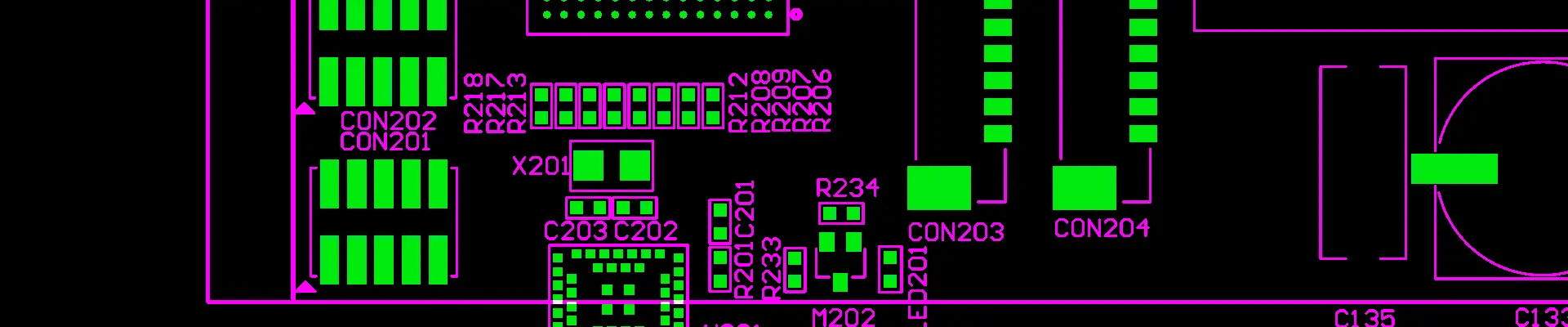

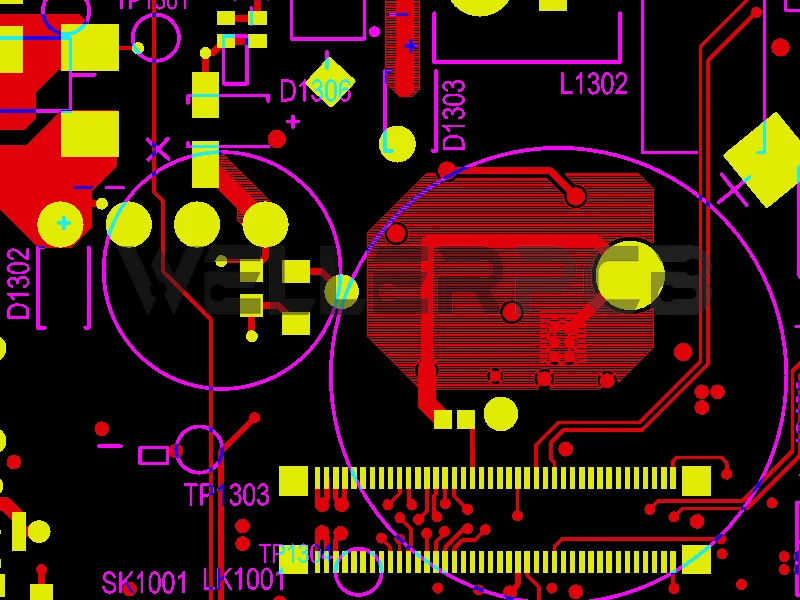

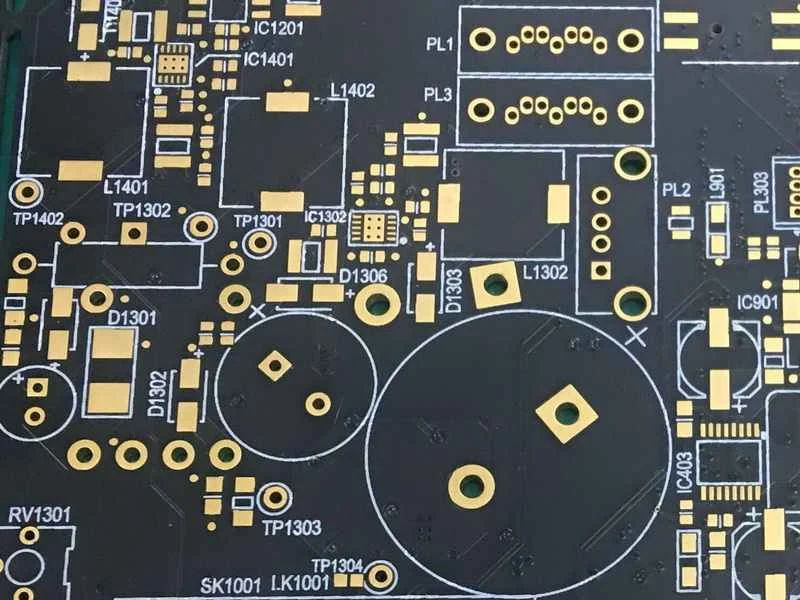

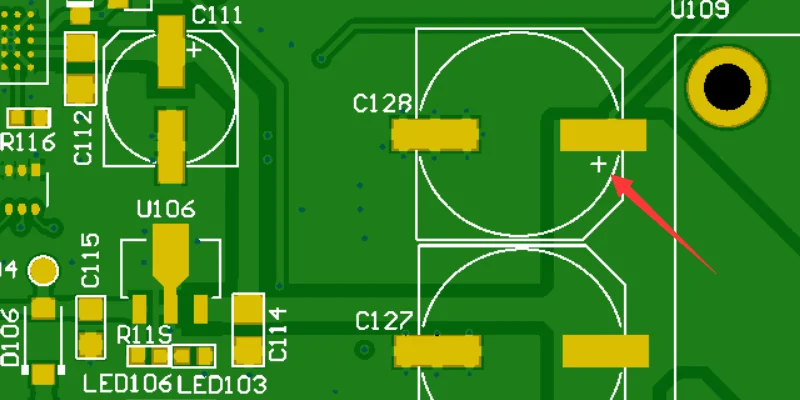

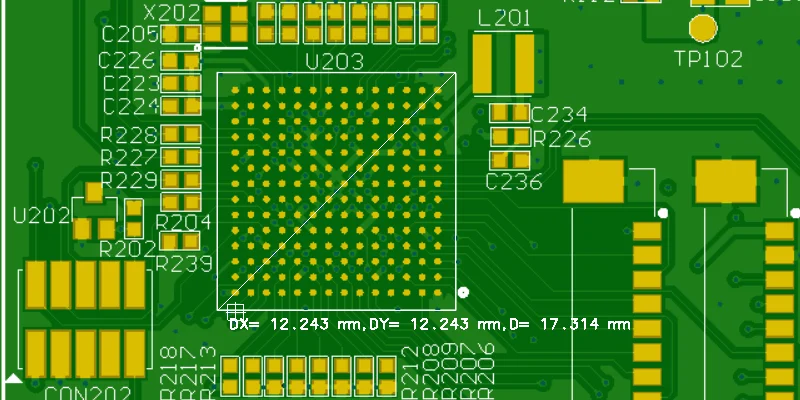

The silkscreen is a typical layer of chemical ink printed on the bare circuit board used to identify the electronic components, Rev. no.#, test points, marks, logos, symbols, etc.

Normally it is printed on the components side or on the solder side, but any side is no matter and can be freely defined by PCB designer as long as it will be as a clear identification to reader as it’s purpose.

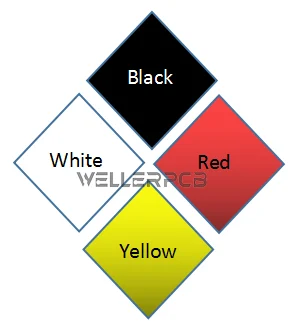

What Types of Colors that PCB Silkscreen Have?

Normally, the white is a generic silkscreen color applied in most of printed circuit boards, which is a common color and friendly to manufacturing process. Meantime, other color such as yellow, red, black is widely used in initial of PCB board design and manufacturing. Pink silkscreen color is also a favorite color to PCB designer but we do not recommend to use this color due to it’s special characteristics with result that unfriendly to manufacturing process.

How It Comes Out By PCB Manufacturing Process?

Commonly there are two production ways to get printed circuit board silkscreen:

One method is done by PCB manufacturers via auto ink printing process as below which a little blurry on the edge of the PCB board. Which sometimes have blurry around the edge of the silkscreen letter.

Basic Notes About PCB Silkscreen Design

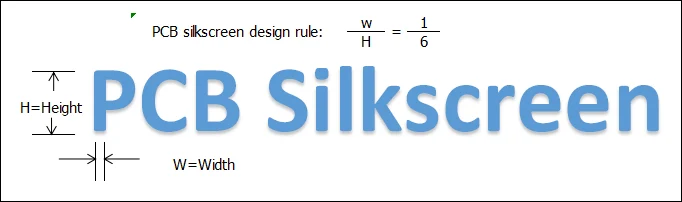

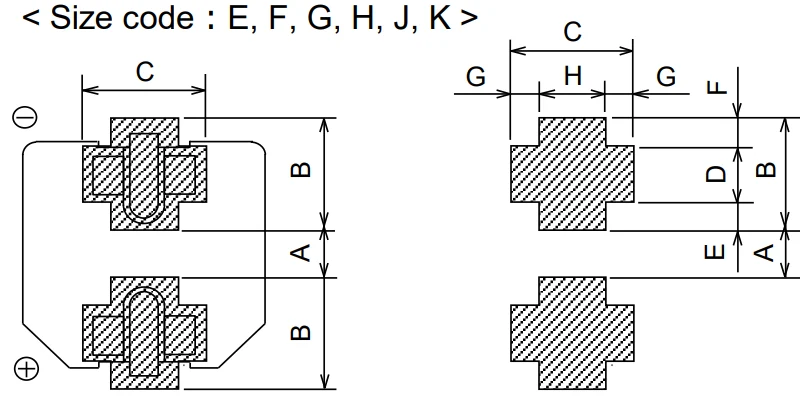

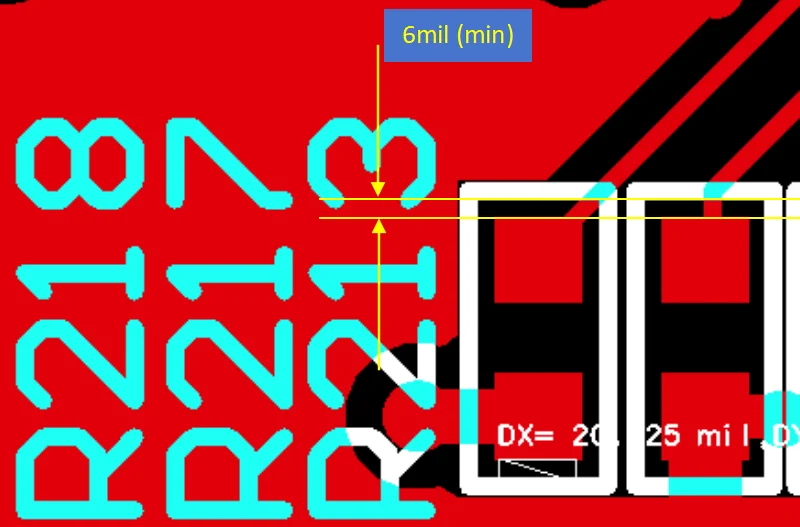

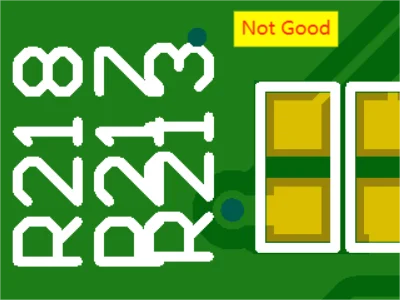

When it comes to PCB layout in silkscreen stage, the design is better to follow this regular ratio that width/height=1:6, which can be sure the silkscreen presented on the complete PCB board at a high resolution performance.

Note that the width of the silkscreen is changing from its different base copper thickness listed as in below table:

PCB silkscreen design guidelines

| Base Copper(oz) | Minimum Silkscreen width (mil) | Silkscreen Height (mil) |

| 0.5 | 4 | 24 |

| 1 | 5 | 30 |

| 2 | 6 | 36 |

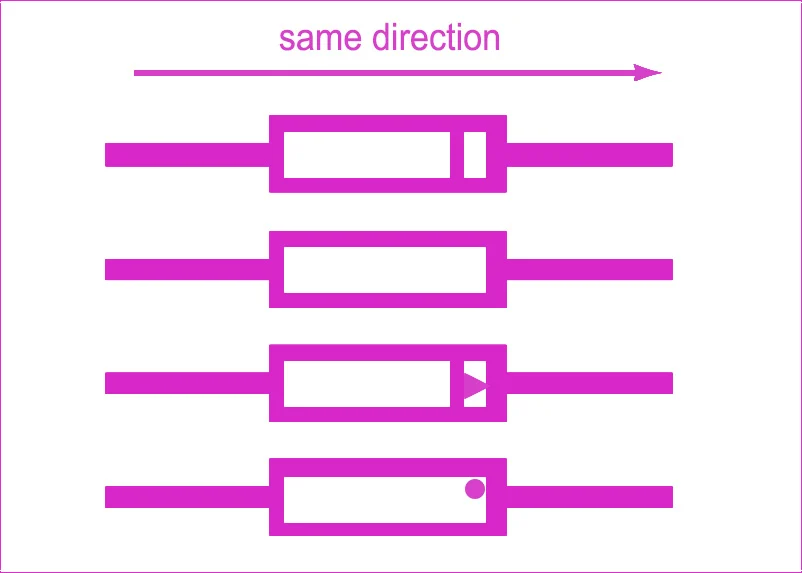

6 Key Points in PCB Silkscreen Design

General Guideline to PCB Silkscreen Design

PCB silkscreen design guidelines

| Base Copper(oz) | Minimum Silkscreen width (mil) | Silkscreen Height (mil) |

| 0.5 | 4 | 24 |

| 1 | 5 | 30 |

| 2 | 6 | 36 |

If you have other concerning about PCB silkscreen before your circuit board design process, please freely contact us via service@wellerpcb.com.