Halogen Free PCB

In our daily life and work, many activities interacted with various of electronic devices, such as refrigerators, a/c, washing machine, vacuum cleaner, microwave oven, etc. Audio and video systems like headphones, DVD players, VCRs, microphones, color TVs, loudspeakers, video game consoles, smartphones, computers, etc.

We do know that the electronic products made of various of materials including chemical, metal, etc. But do we really realize or not that certain substances used in the manufacturing of electronic products may take harm to the human health.

Such as the raw materials used to manufacture printed circuit board, resistors, and capacitors, etc. Even the materials such as solder flux used in PCB assembly process. In this article we mainly discuss that material that used to manufacture printed circuit board with halogen substance in.

What is Halogen Substance?

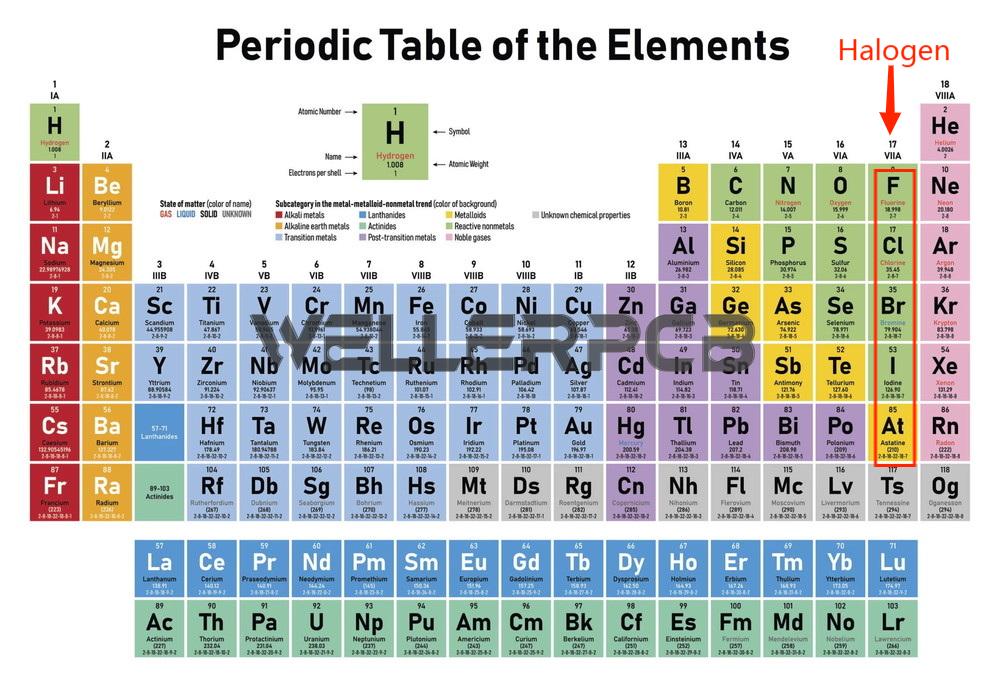

Exactly halogens are the elements listed in group VII including fluorine (F), chlorine (Cl), bromine (Br), iodine (I), and astatine (At), as marked in the following picture. The name halogen was from the Greek roots hal- (“salt”) and -gen (“to produce”). They all in chemical reactions produce sodium salts in similar properties.

Halogens in PCBs

Certainly Bromine and elemental chlorine do not appear in the make-up of electronics due to they are highly toxic, but organobromides with it’s outstanding performance of flame retardants, are widely used in the manufacturing of electronics such as PCBs, molding compounds, adhesives, solder masks, cable insulation and flexible printed circuits.

However, as organic bromides burning hazards effects on humans, more and more companies are selecting Halogen-free printed circuit boards and related components due to environmental, market and legislative factors.

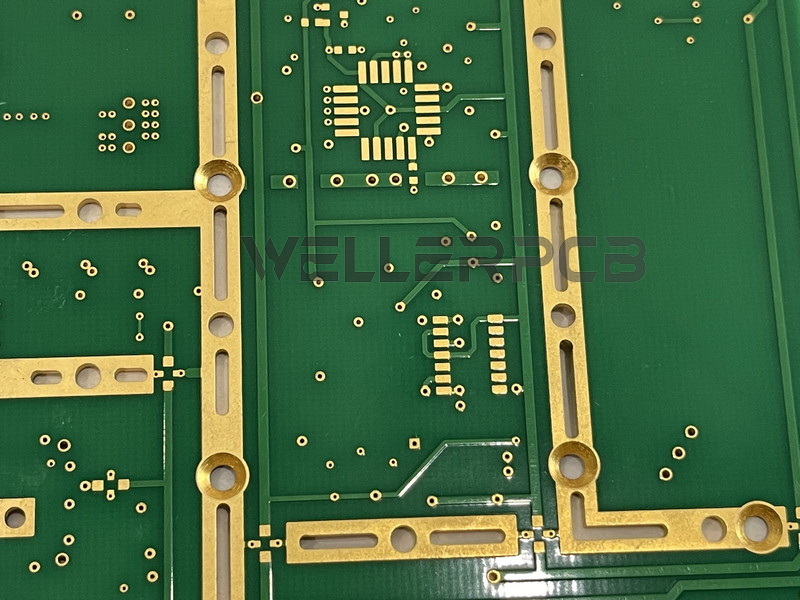

What is Halogen-free PCB?

Typically a Printed Circuit Board with it’s manufacturing material that does not contain halogen elements (Chlorine, Bromine, Fluorine) is considered Halogen-free PCB.

According to the rules of restriction Use of Halogen from the International Electrochemical Commission,a printed circuit board to be specified as halogen-free, it should have less than 900 parts per million of chlorine or bromine, with less than 1,500 ppm of total halogens.

Pros and Cons of Halogen Elements

| Pros | Cons |

| Bromine and chlorine have many benefits that can be used for electronics manufacturing. Chlorine has excellent property of flame-retardant protects the components of a printed circuit board. This is why that most PCBs like CEM3 or FR4 has halogen-containing flame retardants. Chlorine is widely used as an element for coating wires. Somewhere bromine is used as a sterilizing agent. It is also an ideal of flame retardant. | For example, Chlorine or bromine exposure is fatal as it can cause coughing or snoring, nausea, blurred vision, skin discomfort, breathing difficulties, and burning in the eyes. Chlorine-based elements can also combine with hydrocarbons to generate dioxin, which is an extremely deadly carcinogen. |

Halogen Free PCB Design

When you start a halogen-free printed circuit board design, firstly it is importance that you need to know what performance and features that you expect your PCB to perform. And then you’d better to need to communicate with your printed circuit board manufacturer on some critical points:

| 1. Whether they have the ability to make bare printed circuit boards with halogen free materials. |

| 2. Not only in the base material (copper foil, core, prepreg), all other substances they used in the PCB manufacturing process (solder mask, silkscreen) must be 100% with halogen-free. |

| 3. What type of halogen-free base material they have at stock (The stocked material would lower the cost and short the lead time). |

Normally, item 1 is not an issue to most PCB suppliers, item 2 is also not difficult to get that, but for item 3, because there are various of available materials with halogen free from different manufactures that have different features and prices for your decision, so which is extremely a critical choice that possibly directly determine the final performance and cost of your PCB.

How to Select Halogen-free PCB Laminate Material

There are several well-known PCB laminate material manufacturers offering halogen-free laminates and prepregs with varying performance, electrical, physical, and thermal properties.

Typically, the CTE value (Coefficient of Thermal Expansion) of halogen-free PCB laminate materials is lower than regular FR4 PCBs. Additionally, they generally have excellent T-288 times and Td temperatures so as that they can withstand higher reflow temperatures and reflow cycles during PCB assembly process.

The main differences between 7 of the most commonly used halogen-free printed circuit board laminates.

| Manufacturer | Isola | EMC | Panasonic | Panasonic | NAN YA | NAN YA | Shengyi | Kingboard |

| Product | IS550H | EM-370(D) | R-1566W R-1551W | Meg2 (R-1577 R-1570) | NPG-150N | NPG-170N | S1150G | KB-6167G |

| Type | Halogen Free High Tg Epoxy | Halogen Free High Tg Epoxy | Halogen Free High Tg Epoxy | Halogen Free High Tg Epoxy | Halogen Free Mid Tg Epoxy | Halogen Free High Tg Epoxy | Halogen Free Mid Tg Epoxy | Halogen Free High Tg Epoxy |

| IPC-4101E | /127 /128 /130 | /127 /128 /130 | /127 /128 | /127 /128 /130 | /127 /128 | /127 /128 | /127/128 | /127/128/130 |

| Lead Free Process Compatible | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Halogen Free | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| UL Approved | Yes | Yes | Yes | Yes | Yes | Yes | Yes | |

| Flammability UL94 | V-0 | V-0 | V-0 | V-0 | V-0 | V-0 | V-0 | V-0 |

| Tg – Glass Transition Temp ºC (DSC) | 200 | 175 | 148 | 170 | 150 | 170 | 155 | 170 |

| Td – Decomposition Temp ºC (TGA) | 400 | 385 | 350 | 380 | 350 | 360 | 355 | 385 |

| Dk 1 GHz | 1 | 4.10 | 4.60 | 4.14 | 3.8-4.0 | 4.1-4.3 | 4.5 | 4.6 |

| Dk 2-3 GHz | 405 | – | – | – | – | – | – | – |

| Dk 10-12 GHz | 4.43 | 4 | – | – | – | – | – | – |

| Df 1 GHz | – | 0.011 | 0.010 | 0.010 | 0.011-0.013 | 0.009-0.012 | 0.011 | 0.013 |

| Df 2-3 GHz | 0.014 | – | – | – | – | – | – | – |

| Df 10-12 GHz | 0.016 | 0.015 | – | 0.013 | – | – | – | – |

| Moisture Absorption (%) | 0.25% | 0.10% | 0.14% | 0.14% | 0.20-0.30% | 0.20-0.30% | 0.10% | 0.11% |

| CTE Z Axis (ppm/ºC) Pre Tg | 40 | 40 | 34 | 30-50 | 30-50 | 40 | 45 | |

| % CTE Z Axis (50-200ºC) | 0.022 | 0.022 | – | – | – | – | 0.028 | 0.022 |

| Highest of CTE X, Y Axis (PPM/ºC) Pre Tg | 13-17 | 15 | 15 | 16 | 13 | 13 | – | – |

| Number of Lamination Cycles | – | 7 | – | – | – | – | – | – |

| Peel Strength – 1oz (35μm) | 1.45 kN/m | 0.788 kN/m | 1.8 kN/m | 1.3 k N/m | 1.40 kN/m | 1.23 kN/m – 1.57 kN/m | 1.45 kN/m | 1.30 kN/m |

| T288 (with copper) | >60 min. | 60 min. | 3 min. | 25 min. | 5 min. | 5 min. | 45 min. | >60 min. |

| Flexural modulus | – | 0.46 GPa – 0.50 GPa | – | 23 GPa | – | – | – | – |

| Volume Resistivity | 2×107 (C-96/35/90) | 1×1010 MΩ – cm | – | 1×109 MΩ – cm | – | – | – | – |

| Surface Resistivity | 1×108 MΩ | – | – | 1×108 MΩ | – | – | – | – |

| Dimensional stability X-Y axis | – | – | – | – | -0.01-0.03 % | 0.01-0.03 % | – | – |

Applications of Halogen-free PCBs

The more and more printed circuit boards made from halogen-free materials are widely used in the following applications:

| 1. High-speed computing |

| 2. Servers |

| 3. Communication and wireless devices |

| 4. Consumer electronic devices |

| 5. Signaling devices |

| 6. Transportation applications |

In Conclusion

Halogen-free printed circuit boards have become a common choice in most application such as power stations, laboratories, substations, distribution rooms, etc. But, halogen-free PCBs are still much expensive than conventional FR4 PCBs due to material designs, costs of raw materials, and involved complexities. Therefore, you must do some thorough research before decision of selecting this material. Once you know what type of materials you want to use, you can check with our expert to identify the best path forward. You may need to optimize designs or work with our engineering exports on some manufacturing steps to ensure your printed circuit board fabrication can be completed successfully.