Printed circuit board is the core component in any electronic devices, it is manufactured out by complicated production process with composing from copper and other polymer chemical materials. So, does high temperature or high humidity have any impact on PCB’s quality, and lead to failure in final assembly? The answer is yes, of course. Now, let us share with you what impacts from high temperature and humidity will affect a PCB assembly.

Below thoughts of solution could be as a reference on our topic.

The risk of high temperature and humidity can be minimized by conformal coating to functional IC?

Yes, this is a good option to protect circuit from high temperature and humidity. As under-fill techniques helps a lot with high temperature and humidity.

Can the IC exchange verification prove to be a process soldering faults?

No, the operation of replacing the IC has too many side effects. It is recommended to directly do failure analysis to the defective product to find out the cause of the failure.

What or how much does humidity affect process soldering or welding?

Serious impact. High temperature and high humidity will directly affect the product’s performance.

High temperature will cause the stress release of the printed circuit boards to form deformation, and it will also cause embrittlement to some PCB product materials that are not resistant to high temperature. In addition, the speed of heating and cooling will cause different stress pulling effects on products using different expansion coefficients.

Besides oxidizing metal parts, humidity is also a catalyst for electromigration.

For some fine pins or high-density BGA component parts, high temperature and high humidity coupled with the volatilization of the flux will cause a slight of short circuit, which may consume the power of the backup battery, and may cause misoperation on some parts.

Hence, obviously that the PCB assembly manufacturer should have to take correct steps to operate the temperature of the SMT mounting process to protect the circuit board and other electronics parts from potential damage.

Humidity is another enemy to the circuit board and other electronics parts.

All the PCB board before assembly must be purposely stored according to it’s shelf life. The shelf life of the printed circuit boards differ from it’s surface finish.

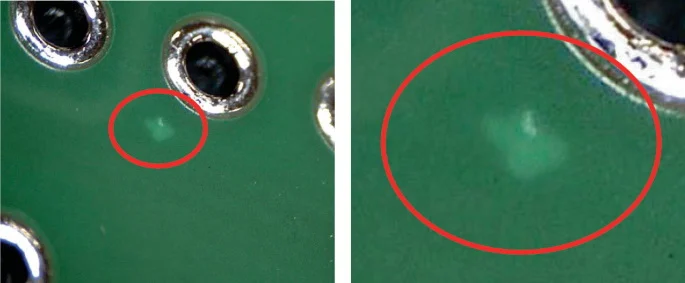

The circuit board will absorb too much humidity from the air if the storage is not dry and comfortable. It would results in the oxiden in the SMT soldering PADs and failure the components assembly. Too much humidity can take PCB layer de-lamination after high temperature in the SMT reflow process.

For any circuit board that freely stored at a long time, it is a necessary process to have these boards to be baked at purpose time and condition to eliminate absorbed humidity (PCB baking process) prior to load them to assembly process.

Now with the increasingly updating precision of electronic products, some aerospace technology and military products also have great requirements in the material storage condition. Then temperature and humidity is not only in step of PCB assembly, but the quality control extended to all the steps from starting to the ending.