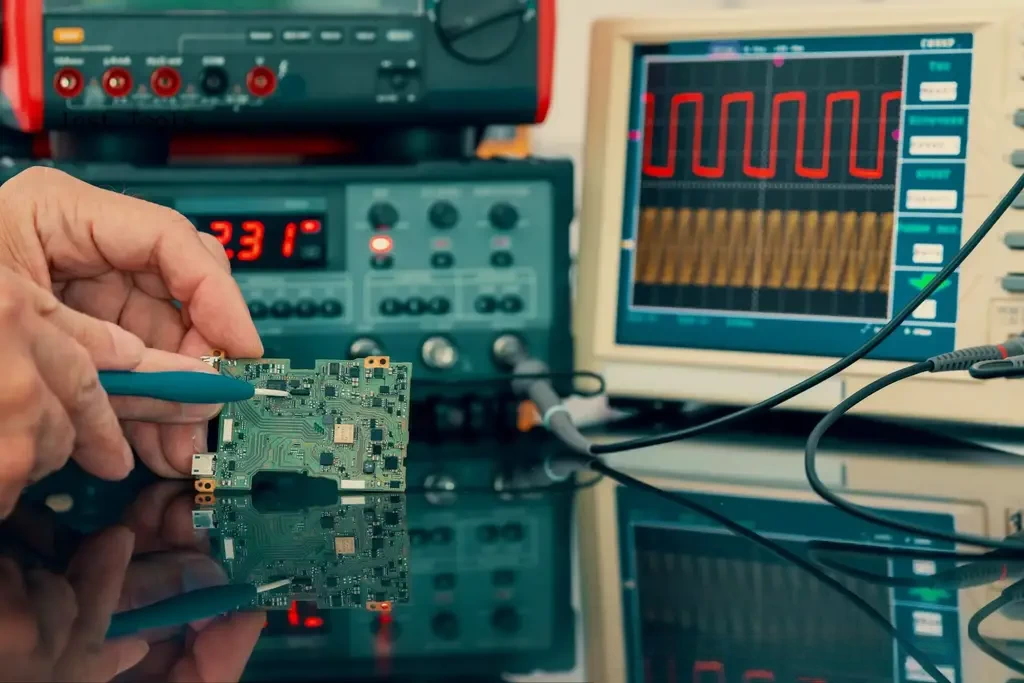

About Printed Circuit Board,What You Need to Know

Printed circuit board or Printed wiring board is a core component in any electronics devices, such as FR4 PCB, Rogers PCB, High Tg PCB, impedance PCB...

The Importance of Copper Pouring In Copper-Free Areas While Creating PCBs

When electronic engineers create printed circuit boards (PCBs), they tend to leave many copper-free areas on the board. They are probably not aware of the technicalities of the PCB production process. A high percentage of the copper-free area on the board can have a negative impact on the product and leave it susceptible to early damage.

PCB Layout Guidelines For SMT Assembly Process Limits

The best optimized PCB layout work will improve the yield in PCB assembly process. The considerations on this article will provide the positive references to PCB layout engineer to generate an effective job.

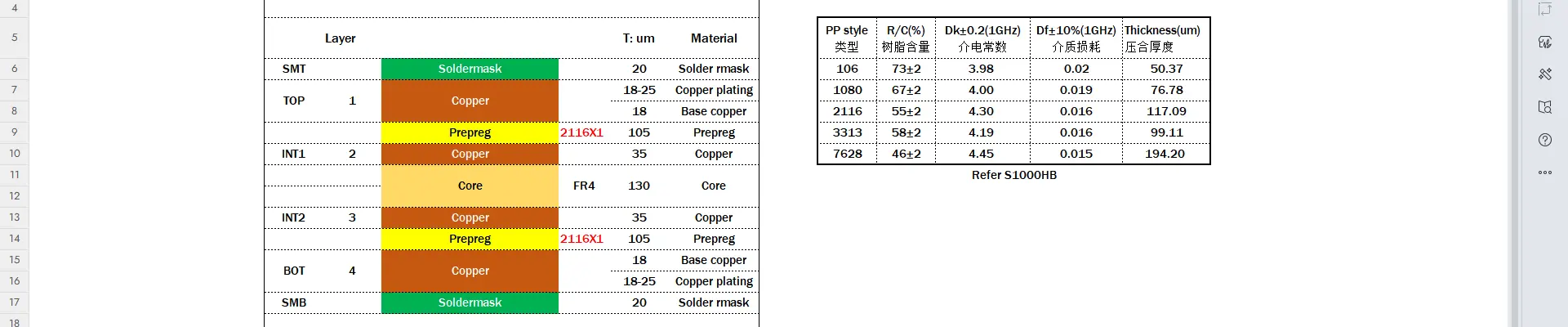

Typical 4 layer PCB Stack-up Design Guidelines

Our standard 4L PCB stack-up design options are suitable for most electronics design with upon global considerations of durable reliability, operation performance, economic cost and more available to PCB manufacturing process

How To Set-up Best Trace Corners in PCB Layout

When an electronic device design finished it’s schematic drawing stage, next phase is to start PCB layout work. So, how to set-up the best track (routing) corners in PCB layout? Which is a better option, 45° corner or rounded corner? Can be layout as 90° corner?

Temperature and Humidity, Harmful to PCB

The circuit board is core component of any electronic device, and once it is corroded by moisture or high temperature, it will rise some quality headaches after PCB assembly process, such as moisture, blister, or layers de-lamination.

An Introduction to Flex Circuit Stiffeners

Stiffeners is an extra special piece of material adhered to specific zone on flexible circuits, which provide necessary rigidizing and support to SMD components assembly on a flex PCB board.

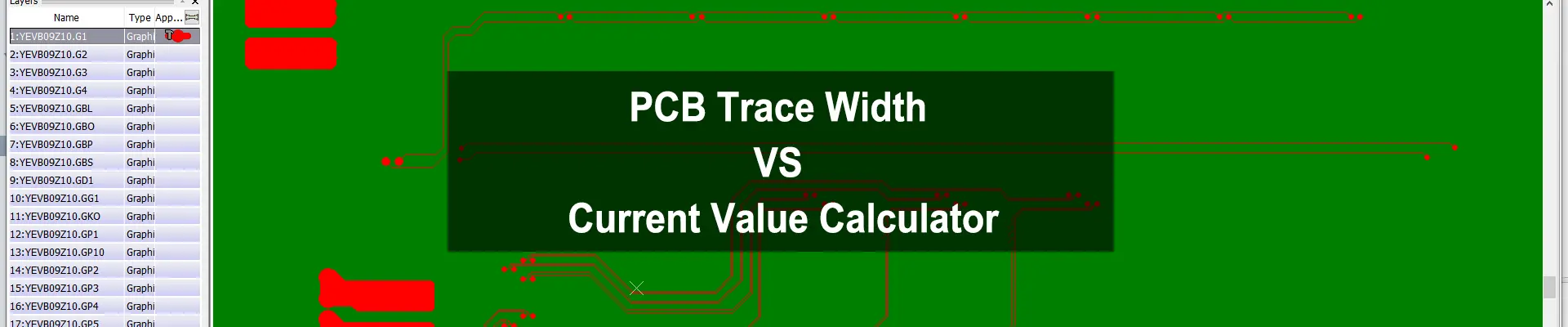

PCB Trace Width VS Current Value Calculator

While you start a PCB design, a typical PCB trace calculator will help you to get the correct copper weight and circuit trace width upon on the basic current that the board run.